The US Coast Guard (USCG) requires an annual inspection for ballast water treatment systems (BWTS), the so-called Annual Check-Up or Annual Compliance Inspection. This inspection is required to ensure that the system complies with established standards and regulations to prevent the spread of invasive species in US waters.

Zeppelin Power Systems performs these check-ups and ensures that your system complies with regulations. You can order the check-up directly with us.

Services of the Annual Compliance Inspection

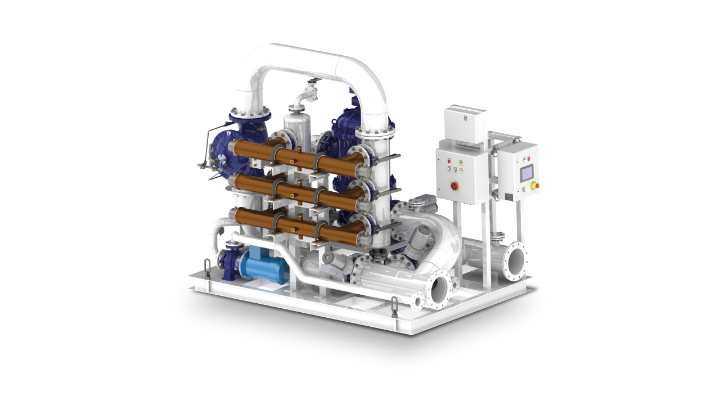

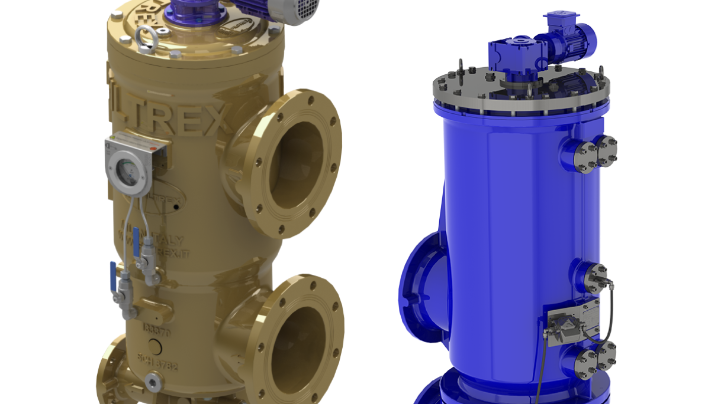

System function tests: Checking the function of all essential components of the BWTS, including filters, UV lamps, pumps and control systems.

Performance verification: Measurement and analysis of system performance to ensure that it effectively meets all requirements for the removal or inactivation of organisms in ballast water.

Monitoring and calibration: Checking the monitoring and measuring equipment and calibrating it to ensure accurate system performance data.

Documentation review: Review operational records and maintenance documentation to ensure that all required inspections, maintenance and repairs have been properly performed and documented.

Visual inspection: Perform a visual inspection of the entire system to detect signs of wear, damage or corrosion that could affect performance.

Safety check: Review all safety precautions and emergency procedures to ensure the system is operating safely and in accordance with regulations. A water test, which is also required, must be carried out by a certified laboratory on site.

Would you like to book an inspection for your ballast water treatment system or receive more information?