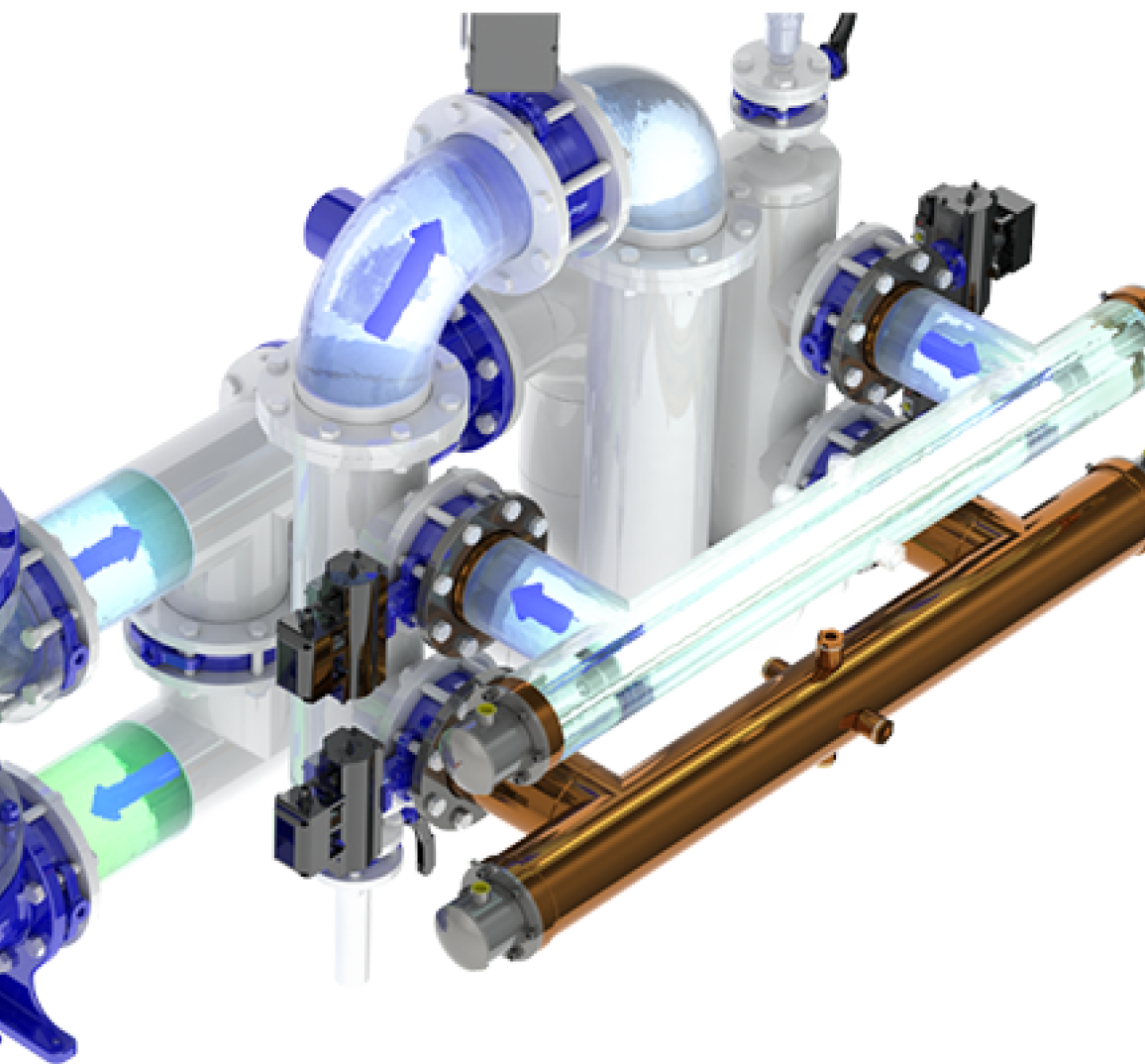

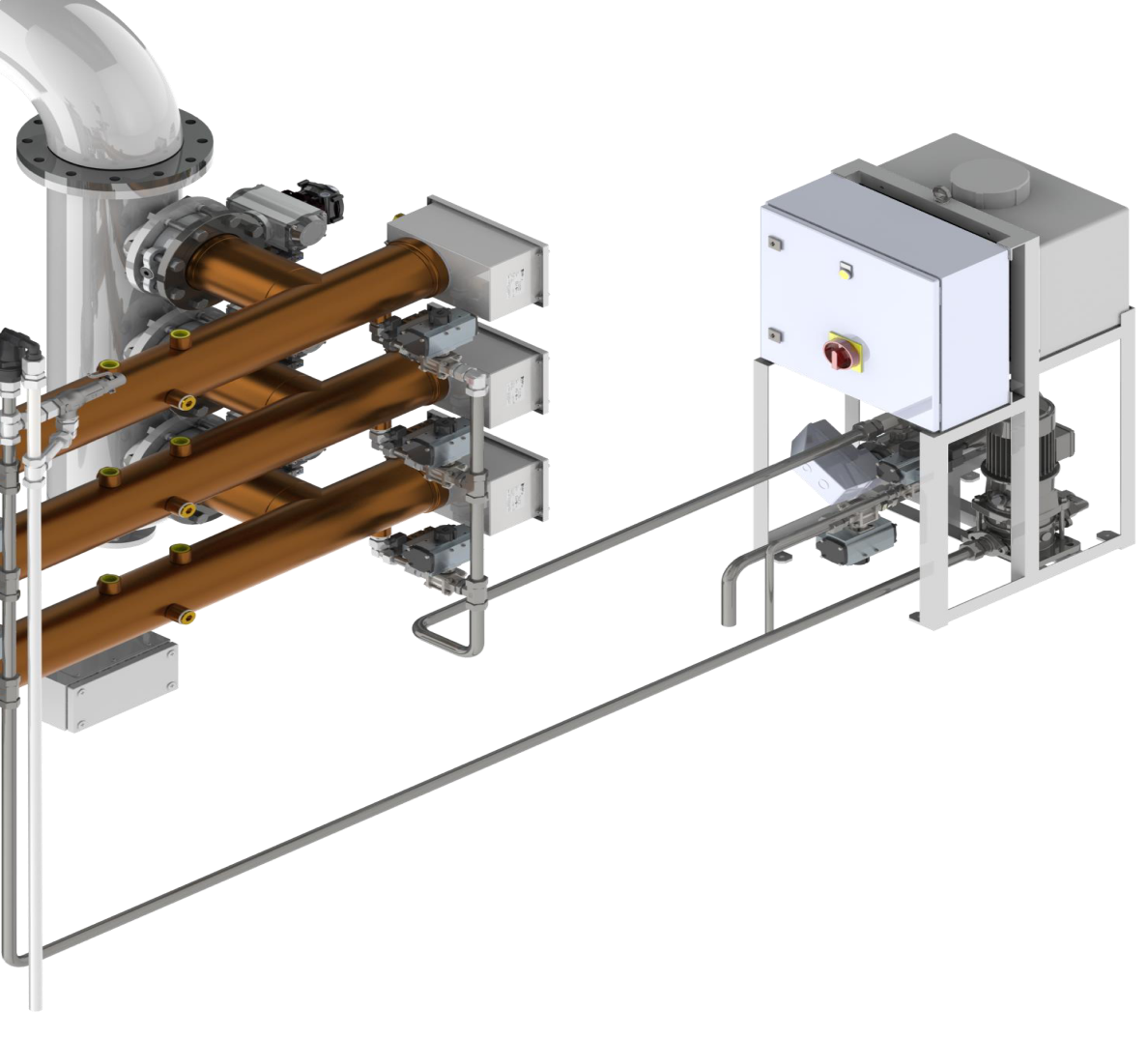

In our ballast water treatment system, the filter plays a crucial role in removing particles from the seawater during ballasting or stripping operations. The filter mesh effectively captures larger particles and prevents them from entering the system.

Key features of our filter technology

Our filter is designed to remove larger particles and organisms from the seawater to ensure optimum water quality.

Minimal pressure drop: With a pressure drop of only 0.1 to 0.5 BAR, our filter ensures efficient flow rates without significant energy consumption.

Bypass function: During deballasting, the filter is intelligently bypassed, enabling smooth and fast water discharge.

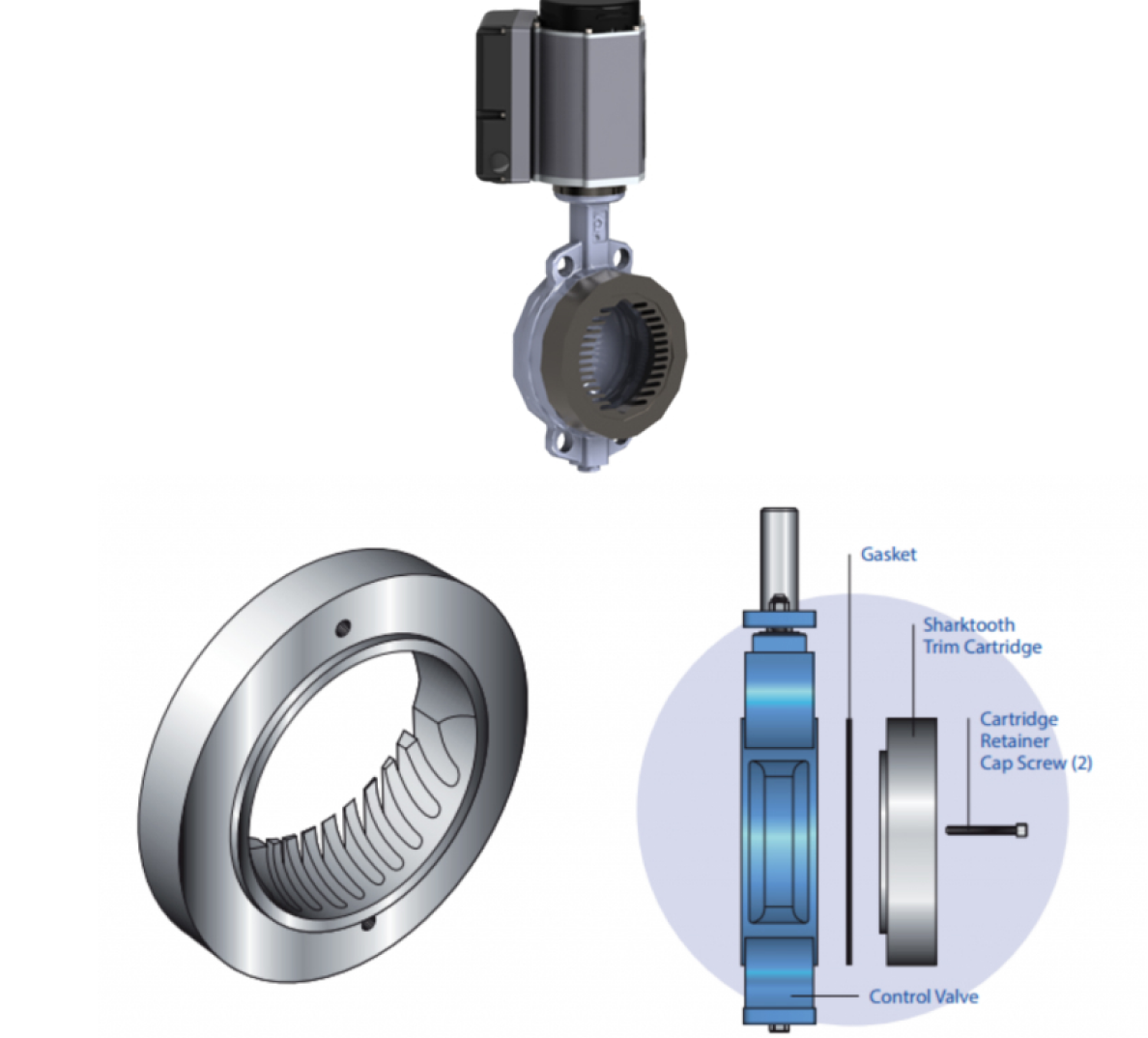

Automatic self-cleaning: Our filter is equipped with an automatic self-cleaning function. By reversing the flow direction and flushing the untreated water back into the sea, continuous filter performance is guaranteed.

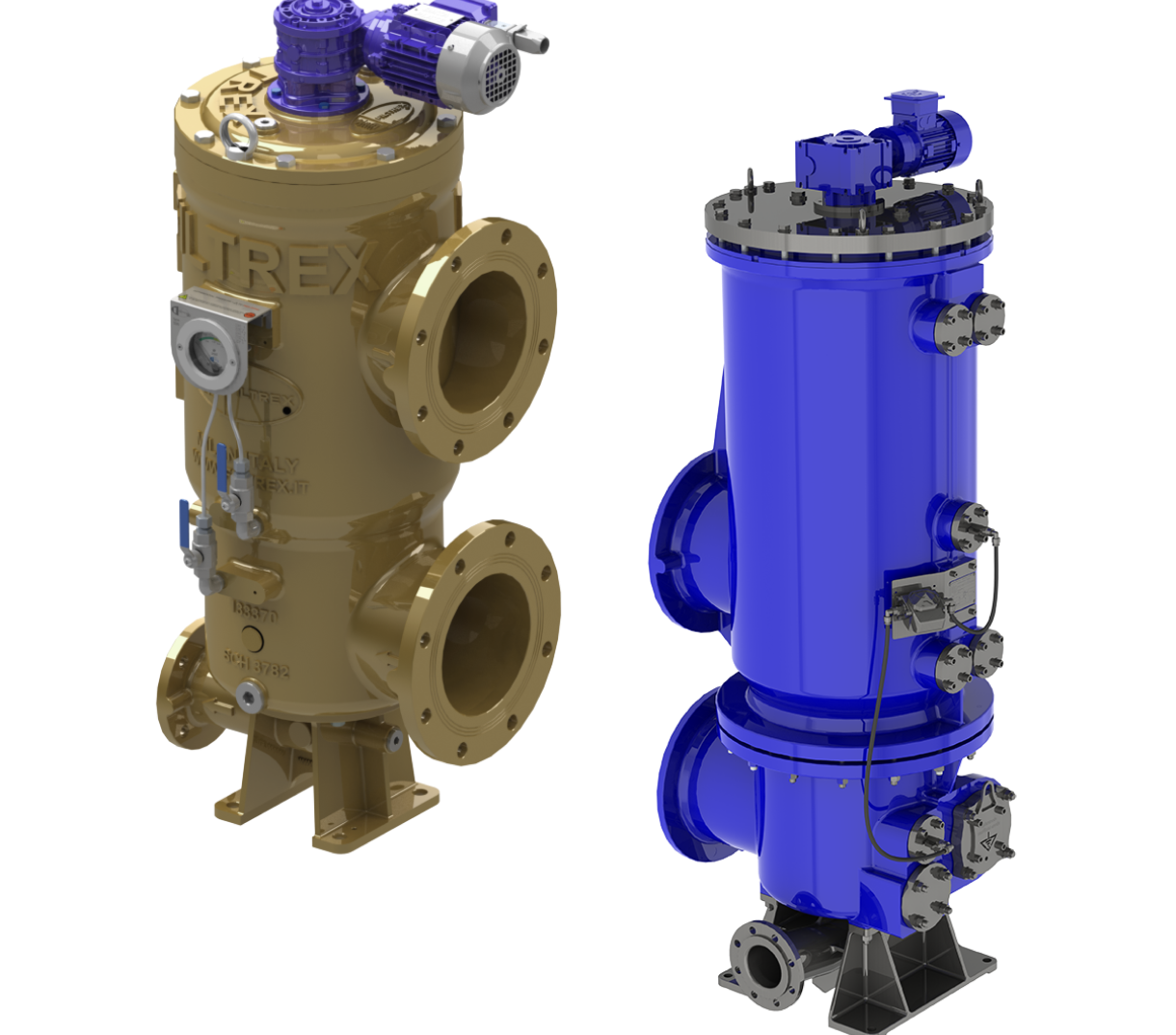

Filter types

Optimarin uses high quality filters in its Ballast Water Treatment Systems (BWTS) to ensure the efficiency and reliability of particle removal from seawater:

Filtrex filter: a basket type filter capable of filtering particles down to 20 microns in size. This filter is known for its high filtration efficiency and robustness.

If you have any questions about our filters, we will be happy to provide you with comprehensive advice.