Drive solutions for demanding workover operations

Fast and reliable wellbore repair with Cat technology

Workover operations are crucial for maintaining well productivity. They include repairing damage, optimizing production performance, and extending the lifespan of wells. Key actions involve re-cementing to stabilize the wellbore wall and sealing work to prevent leaks.

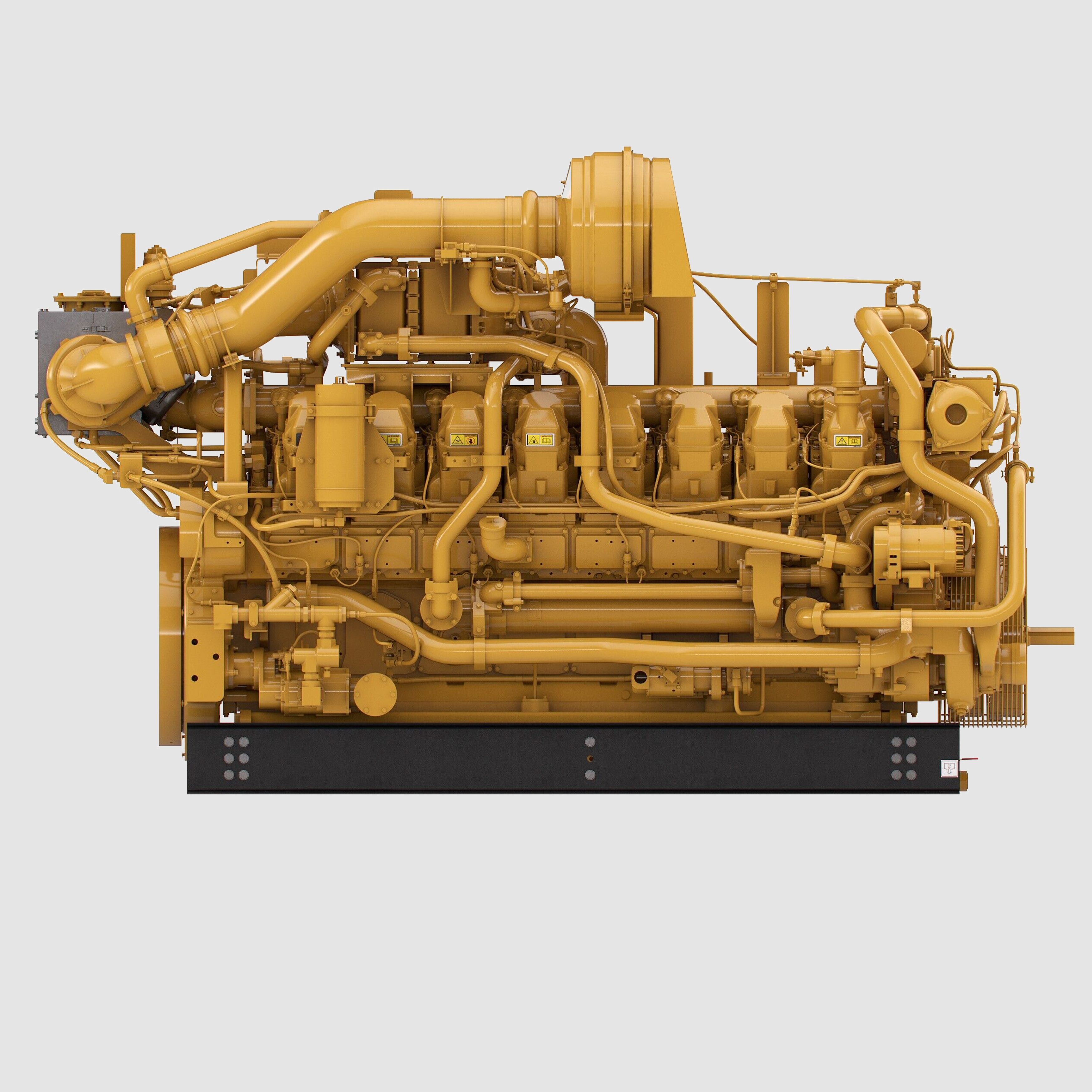

A critical component of effective wellbore repairs is our state-of-the-art drive solutions. By combining our high-quality Cat engines with our extensive expertise and service offerings, we enable our customers in the oil and gas industry to perform wellbore repairs more efficiently and safely. With our solutions, we help optimize the performance of your well.

Available for you 24/7

Germany

International

Key benefits for your organization

Reliability under extreme conditions

Our Caterpillar products are designed for use in harsh conditions. The wellbore environment is often characterized by extreme temperatures, high pressure, and abrasive materials that would quickly wear out conventional equipment. Our Cat engines and gensets are built for longevity and durability, making them ideal for such demanding applications.

Performance and efficiency

The pumps used for re-cementing must generate extremely high pressures to push the cement into the wellbore. Our Cat engines provide the necessary power to operate reliably even under challenging conditions and high loads. This efficiency helps accelerate the cementing process and minimize downtime.

Compact and robust design

Our engines are compact and can be easily integrated into tight spaces on offshore rigs or mobile workover rigs. At the same time, their robust design withstands shocks, high vibrations, extreme temperatures, and corrosive environments, which are common during wellbore repairs.

Precision and control

Thanks to the advanced Cat control systems, our engines and pumps can be precisely managed, which is especially important to ensure that the cement is pumped into the correct areas. This precise control helps prevent leaks and restores the structural integrity of the wellbore.

Comprehensive drive solutions for your workover operations

Zeppelin Power Systems offers a comprehensive service portfolio for wellbore repairs that covers the entire value chain. From customized Cat drive solutions and engineering services to on-site support, digital monitoring systems, and training, we provide holistic support to our customers. Our integrated approach enables efficient and safe workover operations, contributing to the optimization of production, reduction of operational costs, and extension of wellbore lifetimes.

Planning

- Consulting

- Concept Development

- Project Engineering

Engineering

- Electrical & Installation Planning

- Process Technology

- CAD-based Planning

Project Management

- Site Management

- Technical Procurement

- Quality Assurance

Plant Construction

- Electrical Installation

- Assembly

- Commissioning and Test Run

Service

- Maintenance

- Routine Servicing

- Troubleshooting Service

Zeppelin Power Systems Solutions for Oil & Gas

Mobile container solutions for wellbore repair drive systems

Flexible infrastructure for power supply in wellbore repair

Zeppelin Power Systems offers customized container solutions for the oil and gas industry, which prove essential in wellbore repairs. Since these repairs often take place in remote or extreme environments, the mobile and flexible containers provide optimal infrastructure for the safe and efficient operation of drive systems and power generation equipment.

With their ATEX certification, they are ideal for work in explosive environments, which are common during wellbore repairs, as these operations often involve gases and other hazardous materials. The container solutions, with their modular design, allow for quick transport and on-site assembly.

What technologies are used in workover operations?

Workover operations play a crucial role in the oil and gas industry, especially when it comes to restoring or increasing the productivity of a well.

Technologies used in workover operations

Specialized technologies and tools are required for workover operations to repair the wellbore. One central technology commonly used is coiled tubing. This is a continuous steel pipe wound on a drum that can be inserted into the wellbore without joints. Coiled tubing is used for various tasks, such as injecting chemicals, removing deposits, or sealing leaks.

Another important tool is wireline and slickline technologies. These thin, but extremely durable cables are lowered into the wellbore to deploy measurement instruments or tools. Wireline is often used to collect data about the wellbore's condition, while slickline is used for mechanical tasks such as installing or removing valves and other components.

Cementing involves pumping cement under pressure into leaking or damaged areas of the wellbore. This technique is commonly used to seal leaks in casing or stop unwanted fluid flows. The cement hardens and forms a barrier that restores the integrity of the wellbore.

Mixing and hydration units are used to create cement mixtures and chemical solutions on-site and pump them into the wellbore. They ensure that the correct chemical properties are available for the repair processes.

Drive systems and power supply for workover operations

Since wellbore repairs often take place in remote areas or under extreme conditions, the engines and generators driving the tools must not only be powerful but also robust and reliable.

For conducting workover operations, mobile power units are often required, which are flexible and portable to be deployed in hard-to-reach regions. These mobile solutions provide a reliable power supply and are specifically designed for operation in harsh environmental conditions.

Another key aspect of the drive systems for workovers is their power and efficiency. These engines must be capable of driving a variety of tools simultaneously without sacrificing efficiency. They often offer high power density to operate the required equipment safely and in a controlled manner. Modern diesel generators and electric motors are commonly used due to their reliability and ability to work continuously even under challenging conditions.

Zeppelin Power Systems Solutions for Oil & Gas

Efficient complete solutions for your drilling projects

Show all Solutions for Oil & GasZeppelin Power Systems Products For Oil & Gas

Powerful Cat products for your wellbore repair

Show all Products for Oil & GasFor the demanding processes of wellbore repair, Zeppelin Power Systems offers reliable and powerful Cat engines. These engines are perfectly adapted to the specific challenges of the oil and gas industry, delivering consistently high efficiency even under extreme conditions.

Zeppelin Power Systems Resources for Oil & Gas

Brochures and certificates for Oil & Gas available for download

Show all Resources for Oil & Gas

High-Performance Drives for Fracking Trucks – Precision & Efficiency | Zeppelin Power Systems-Engine Ratings Guide

Engine Ratings Guide

High-Performance Drives for Fracking Trucks – Precision & Efficiency | Zeppelin Power Systems-You can find more information about our Well Services in the brochure

You can find more information about our Well Services in the brochure

Zeppelin Power Systems Portfolio

Explore more from the Zeppelin Power Systems portfolio

Power & Heat

Rail

© 2025 Zeppelin Power Systems GmbH