Robust drive solutions for oil and gas production

With our drive systems, you unlock the full potential of your upstream production

Our customized drive systems for pumps and compressors provide the necessary power and efficiency to optimize the demanding processes of oil and gas production. From extraction and pressure maintenance to gas compression, our solutions ensure maximum performance with minimal energy consumption.

Zeppelin Power Systems complements this portfolio with extensive technical services, including maintenance, spare parts supply, and technical training, to ensure the reliable and efficient operation of your systems.

Available for you 24/7

Germany

International

Key benefits for your organization

Reliable in operation

Our drive solutions ensure smooth operation and are designed for maximum uptime. With robust construction and durable components, they guarantee that your production processes run without interruptions.

Customized for your requirements

Every production environment presents different challenges – that's why we offer tailored drive solutions. From power design to special safety measures such as explosion protection, we customize our systems to meet your specific needs.

Explosion-proof solutions

In explosion-hazardous areas, which are common in oil and gas production, our engines and gensets can be housed in ATEX-certified containers, meeting all safety requirements.

Used worldwide

Cat engines and gensets are used worldwide in both onshore and offshore production, proving their reliability under the most diverse conditions. Thanks to our global presence and extensive service network, we are able to provide fast support at any time.

Zeppelin Power Systems Solutions for Oil & Gas

We find the right engine solution for every production condition

Drive solutions for oil and gas production must provide the highest level of operational safety and performance under extreme conditions to meet all requirements. Our production engines offer power ranges from 328 bkW to 1,230 bkW. For power generation, Cat generators are available with capacities ranging from 280 ekW to 5,875 ekW at 50 Hz, and from 114 ekW to 4,840 ekW at 60 Hz.

Optimized technology for varying wellbore conditions

Zeppelin Power Systems offers customized drive solutions that can be perfectly adapted to the specific conditions of each wellsite. Since every wellbore is unique, the engine is precisely tailored to the respective requirements. We consider factors such as the volumes to be produced, the prevailing pressure, and the specific site conditions. Whether high pressure, deep production, or extreme environmental conditions – our solutions guarantee maximum efficiency and performance, tailored to your specific production processes.

From heavy crude oil to light crude

The pumpability of crude oil is heavily influenced by the type of crude oil and the production region. In colder environments, such as offshore facilities or Arctic regions, the oil is often too viscous to be pumped easily. This is where the modern technology of our Cat engines comes into play: the waste heat is used through heat exchangers to warm the crude oil, reducing its viscosity and increasing flowability. Lighter oils, on the other hand, can be pumped directly without complex processes like cracking or refining and can even be used to power the engines. This flexibility makes our drive solutions the ideal choice to ensure reliable operation under various conditions.

Do you have questions about our production solutions? We are happy to advise you.

Zeppelin Power Systems Products For Oil & Gas

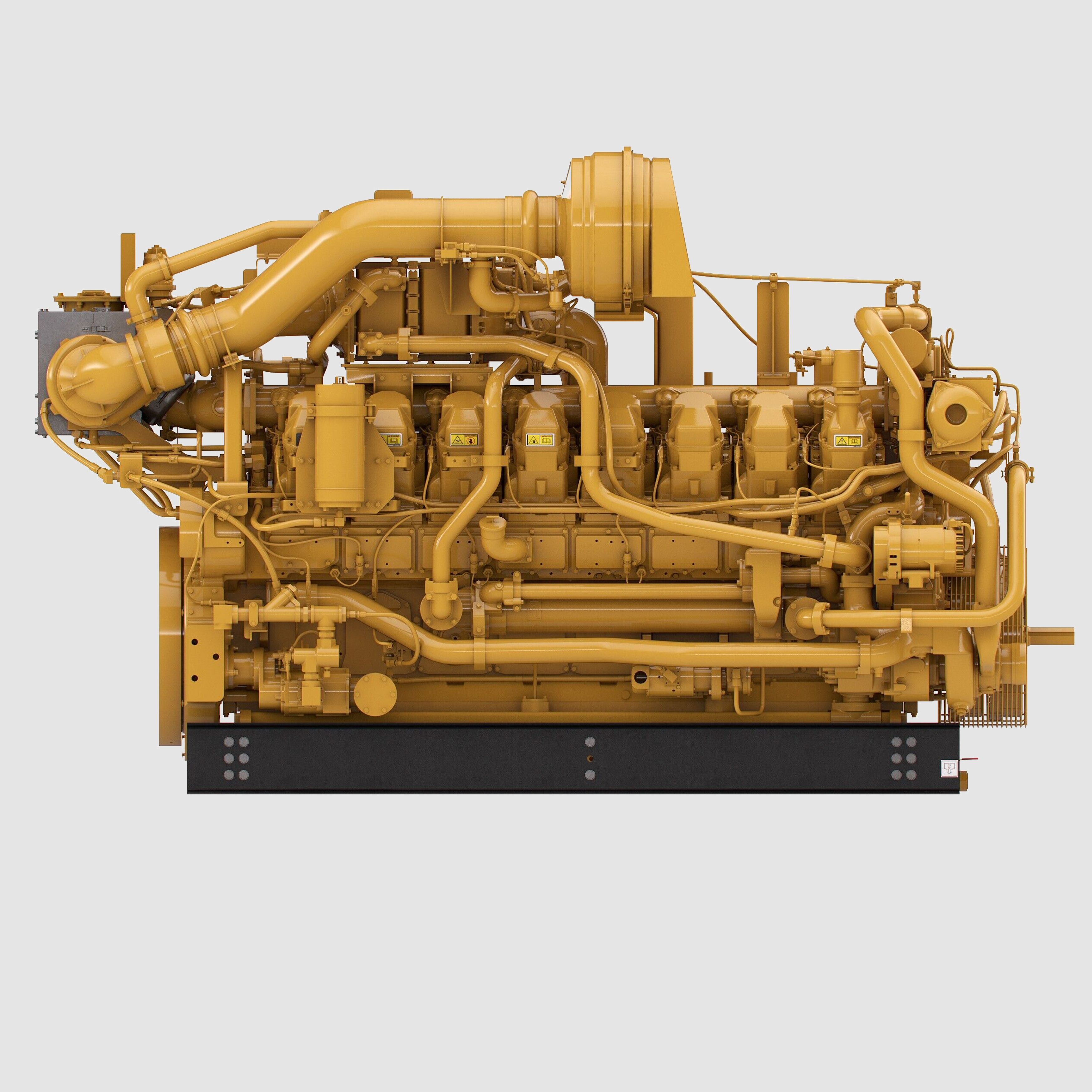

Drive power from Caterpillar for pumping and compressor systems

Oil and gas production places high demands on the pumps and compressors used. They must withstand extreme operating conditions such as high temperatures, corrosion, and strong vibrations. Pumps need to be capable of consistently moving large volumes at high pressures, while compressors must maintain high pressures for the compression and transport of gases. Our engines and gensets provide optimal support for these tools.

Ideal for pump drive: engines with high efficiency at variable speeds

Diesel and gas-powered generators from Cat, available in the power range of 280 kW to 5,875 kW, are the preferred pump drives in many applications worldwide. With a mechanical efficiency of up to 48%, they utilize available energy with exceptional efficiency. Even at variable operating speeds, the efficiency remains high, increasing their flexibility in use. Thanks to easy startup and simple operation, the engines are particularly user-friendly. Additionally, they are highly tolerant of fuels of varying quality, making them robust and reliable in diverse applications.

Gas engines for compressors

The Cat gas engines from the G3300, G3400, G3500, G3600, and CG137 series are ideal for driving compressors. The integration of ADEM™ A4 technology in these engines allows for precise fuel control and the use of the produced gas as fuel.

Would you like to learn more about our engines? We are happy to advise you.

We are your expert for the safe and efficient operation of your oil and gas production facilities

We are your reliable expert when it comes to the safe and efficient operation of your oil and gas production facilities. With our years of experience and extensive expertise, we ensure that your facilities run smoothly and meet the highest safety standards.

Planning

- Consulting

- Concept Development

- Project Engineering

Engineering

- Electrical & Installation Planning

- Process Technology

- CAD-based Planning

Project Management

- Site Management

- Technical Procurement

- Quality Assurance

Plant Construction

- Electrical Installation

- Assembly

- Commissioning and Test Run

Service

- Maintenance

- Routine Servicing

- Troubleshooting Service

Zeppelin Power Systems Solutions for Oil & Gas

Flexible container solutions for your oil and gas production

Mobile and customizable infrastructure for remote and harsh environments

Our container solutions offering includes mobile power supply – all in compact, portable containers.

Our customized container solutions offer significant advantages:

- Quick readiness for deployment

- Easy transport to remote locations

- Modular expandability

- Robust construction for extreme conditions

- Explosion-proof containers

Of course, our containers meet the highest safety standards (DNV) and are internationally certified.

Oil and gas production

The production of oil and gas begins after successful drilling and involves the process of bringing the found oil or gas from the reservoir to the surface. Initially, oil or gas can often flow to the surface naturally due to the pressure in the reservoir. The natural reservoir pressure pushes the resources upwards, through the wellbore, to the surface.

Once the reservoir pressure is no longer sufficient to bring the oil or gas to the surface, artificial lifting methods (wellbore stimulation) are used. The pumps required for these processes are powered by our high-performance engines and gensets. Deep pumps (sucker rod pumps) operate mechanically and are commonly used in onshore facilities. They consist of a long rod driven by a surface motor. The rod moves up and down to pump oil from the wellbore. Electric submersible pumps (ESPs) are installed directly in the wellbore. They pump the oil up through an electric drive. ESPs are particularly useful for deep wells and higher production volumes.

Production infrastructure

Once the oil or gas reaches the surface, it is controlled and processed by various equipment. The Christmas Tree is a collection of valves, pressure regulators, and pipes that control the flow of oil or gas at the surface. It also ensures that the pressure in the wellbore is monitored and that the production rate can be adjusted or the wellbore can be safely sealed if needed. In gas fields, compressors are used to pressurize the natural gas, allowing it to be transported through pipelines or further processed. They are also necessary when the produced gas is reinjected into the reservoir (gas injection).

Transportation and storage

The produced oil or gas is transported to processing facilities or storage sites through pipelines, or by trucks and ships, after separation and processing. Storage tanks and containers are often used to ensure that the oil or gas can be safely stored before it is further transported.

Monitoring and automation

In modern oil and gas production facilities, a variety of sensors and monitoring systems are used to control the pressure, temperature, and flow of resources in real-time. This data is monitored in central control rooms, and in the event of deviations, automatic controls can adjust the production process to ensure safety and efficiency.

Zeppelin Power Systems also offers digital solutions that enable continuous analysis of operational data and proactive maintenance of facilities. These solutions help detect potential issues early and optimize maintenance cycles, contributing to higher availability and longer lifespans of drive and generator systems.

Zeppelin Power Systems industries

Customized drive solutions for FPSO, fracking, and more

We offer customized drive and energy system solutions from Cat specifically for oil and gas production. Our robust engines and generators support applications such as FPSO units, fracking trucks, mobile drilling rigs, and offshore platforms with the highest efficiency and reliability. For precise control and reliable operation under extreme conditions, our systems are also ideal for wireline and slickline services.

Zeppelin Power Systems Solutions for Oil & Gas

Customized complete solutions for drilling projects in the oil and gas industry

Show all Solutions for Oil & GasZeppelin Power Systems Products For Oil & Gas

Maximum performance for your production processes with Caterpillar products

Show all Products for Oil & GasZeppelin Power Systems Resources for Oil & Gas

Brochures and certificates for Oil & Gas available for download

Show all Resources for Oil & Gas

High-Performance Drives for Fracking Trucks – Precision & Efficiency | Zeppelin Power Systems-Engine Ratings Guide

Engine Ratings Guide

High-Performance Drives for Fracking Trucks – Precision & Efficiency | Zeppelin Power Systems-You can find more information about our Well Services in the brochure

You can find more information about our Well Services in the brochure

Zeppelin Power Systems Portfolio

Explore more from the Zeppelin Power Systems portfolio

Power & Heat

Rail

© 2025 Zeppelin Power Systems GmbH