Powerful energy and drive solutions for oil and gas drilling

Onshore drilling with the robust engines and gensets from Caterpillar

Powerful and robust drive systems are the core of modern onshore drilling rigs. They must withstand extreme loads and function reliably under harsh environmental conditions. Zeppelin Power Systems offers high-performance systems for the upstream phase in the oil and gas industry.

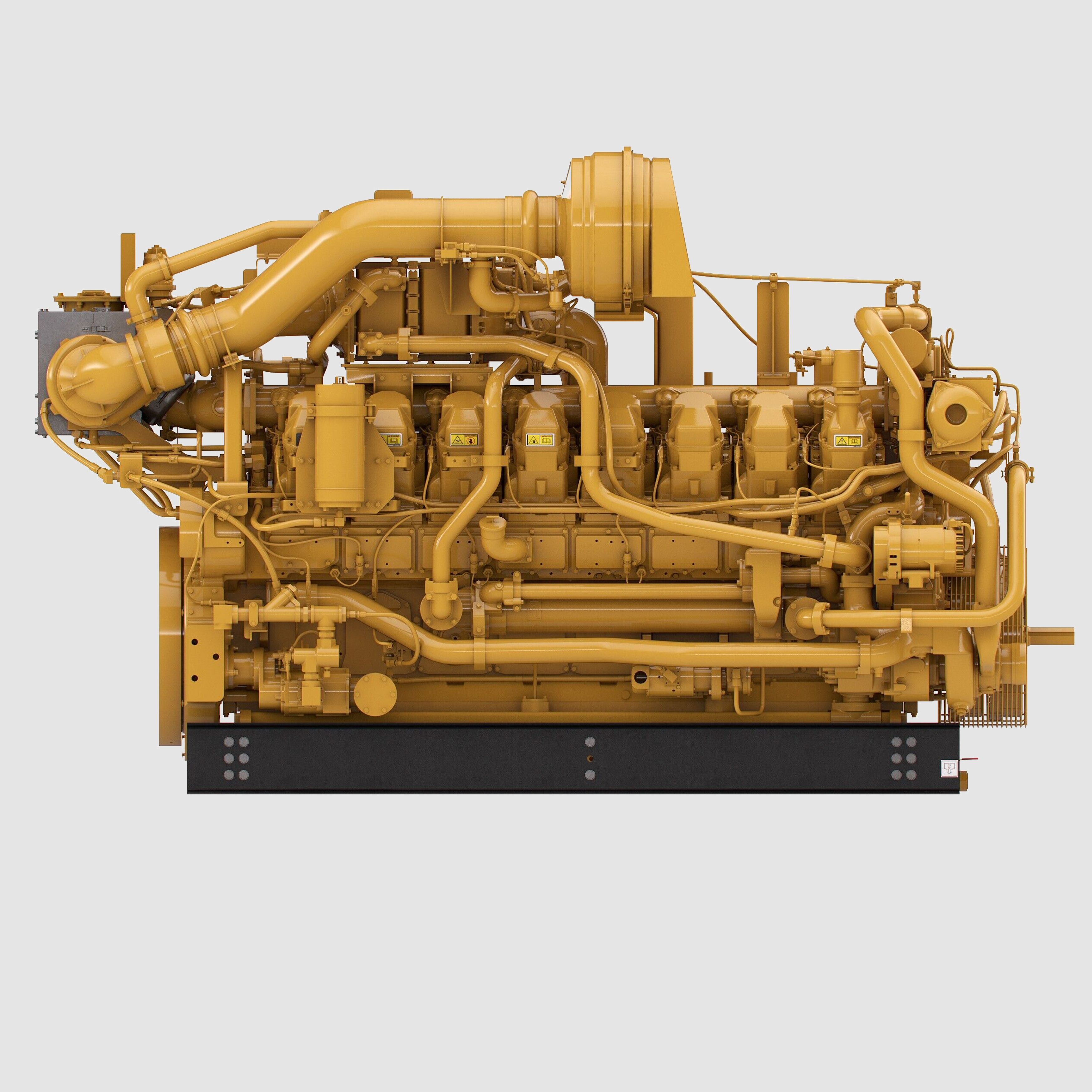

Our drilling solutions are based on robust Caterpillar engines, which impress with high power density, reliability, and efficiency. They provide the necessary power to drill precisely through deep layers and hard rock to reach oil and gas reserves. Our powerful gensets supply energy to onshore drilling platforms and drive critical pumping systems, mud pumps, and cementing equipment.

Available for you 24/7

Germany

International

Key benefits for your organization

Powerful and reliable

Our Cat engines and gensets deliver exceptional power and endurance required for deep drilling. The high power density enables efficient drilling processes even under extreme conditions, and the constant performance minimizes costly downtime.

Designed for extreme environments

The robust construction and high-quality design of our drilling drives ensure a long lifespan even in harsh environments. Our Cat products are specifically designed for use in extreme conditions, such as high temperatures, dust, and vibrations.

Service, expertise, and experience

Zeppelin Power Systems brings decades of experience and extensive expertise in the oil and gas industry. Our globally extensive service network ensures reliable support worldwide, even in the most remote locations.

Customized solutions

We offer customized solutions that meet the specific requirements of the oil and gas industry. These tailored approaches ensure maximum efficiency and performance of the drilling rigs.

Maximum performance and efficiency in drilling

For drilling operations, drilling rigs typically require 7.5 MW of power to move heavy drill strings and drive the drill bit into the rock. We offer customized solutions that reliably meet the high demands of drilling rigs. Our powerful gensets provide the necessary energy to power the electric drives and are also available as container solutions, known as "powerhouses."

Our robust drives are designed for operation under extreme conditions such as high temperatures and strong vibrations. With our extensive expertise, we customize each component to meet your specific drilling requirements—whether under challenging geological conditions, extreme weather, or maximum power demand.

Drives for pumps and cementing equipment

For the operation of critical pumping systems, Zeppelin Power Systems offers powerful Cat gensets. These units provide the necessary energy to essential components such as mud pumps and cementing equipment.

Our customized solutions ensure seamless integration into existing systems. By using the latest technology and materials, we ensure that your facility operates not only efficiently but also safely and environmentally responsibly.

Do you have questions about our drilling solutions? We are happy to advise you.

Zeppelin Power Systems Products For Oil & Gas

Reliable supply with top-class engines and gensets

High-performance engines

The core of our drilling solutions consists of robust Caterpillar engines, which are used to drive the drilling systems and meet every requirement of your drilling rig. With their power, they enable precise drilling to great depths and through the hardest rock, while maintaining optimized fuel consumption. Our standard range includes engines C15, C18, C27, C32, 3508, 3512, and 3516, with power ratings from 320-1300 ekW, available for both 50 or 60 Hz applications.

Efficient power supply with Cat gensets

Our gensets drive mud pumps and cementing equipment and are available in the power range of 86 to 17,460 ekW, with options for 50 or 60 Hz. Due to their reliability, durability, and serviceability, our 3500 series gensets are particularly valued. In particular, the 3512B genset with "Dynamic Gasblending" allows the use of both diesel and produced gas as fuel, resulting in significant fuel cost savings. Additionally, we offer gensets based on gas engines in the power range of 86 to 9,760 ekW as package solutions.

Cat products are robustly designed and built for continuous operation. For critical applications, such as pipeline service, we also offer ATEX-compliant engines. They ensure stable operation even under the most challenging conditions, contributing significantly to the efficiency and safety of the entire drilling rig.

Zeppelin Power Systems Solutions for Oil & Gas

Flexible container solutions for the oil and gas industry

Mobile and customizable infrastructure for remote and harsh environments

Our container solutions offering includes mobile power supply for compressor units and drilling drives – all in compact, portable containers.

Our customized container solutions offer significant advantages:

- Quick readiness for deployment

- Easy transport to remote locations

- Modular expandability

- Robust construction for extreme conditions

- Explosion-proof containers, for example, near wellbores or gas processing facilities

Of course, our containers meet the highest safety standards (DNV) and are internationally certified.

We are your expert for the safe and efficient operation of your drilling rigs

We are your expert for drive and energy systems in the upstream and midstream phases of oil and gas production. With Zeppelin Power Systems as your partner, you benefit from comprehensive, customized solutions and services that maximize the efficiency and reliability of your drilling rigs. Our services include drives for the drilling process and wellbore stimulation, gas compression systems, comprehensive well services, and innovative battery storage system solutions for your drilling rigs. As an experienced and knowledgeable partner, we support you in successfully implementing your projects in the oil and gas industry.

Planning

- Consulting

- Concept Development

- Project Engineering

Engineering

- Electrical & Installation Planning

- Process Technology

- CAD-based Planning

Project Management

- Site Management

- Technical Procurement

- Quality Assurance

Plant Construction

- Electrical Installation

- Assembly

- Commissioning and Test Run

Service

- Maintenance

- Routine Servicing

- Troubleshooting Service

Robust energy systems for onshore drilling

Onshore drilling is an established method for extracting oil and gas, where drilling rigs are set up on solid ground. The drilling sites are located in various landscapes, from deserts and forests to populated areas. One advantage over offshore drilling is the lower costs for transportation and infrastructure. Additionally, safety risks are lower as land-based drilling can be more easily monitored.

Various techniques are used in onshore drilling, including vertical drilling, where a wellbore is drilled vertically into the earth, and horizontal drilling, which is useful for reservoirs that spread out horizontally. Rotary drilling techniques drive the drill bit into the rock through rotation, while hydraulic fracturing (fracking) uses high-pressure fluids to access hard-to-reach reservoirs. Other techniques include underbalanced drilling, managed pressure drilling, coiled tubing drilling, and casing while drilling.

Zeppelin Power Systems offers robust drive and energy systems for all drilling techniques, ensuring reliable performance even under extreme conditions. The engines and transmissions are designed to withstand high loads and vibrations, which is particularly important in rotary drilling, where significant pressure is applied to the drill bit. In remote areas, our gensets ensure continuous power supply. Additionally, Zeppelin Power Systems provides solutions tailored to challenging geological conditions, such as hard rock layers. The powerful Cat engines ensure smooth drilling, and the efficiency of the energy systems helps optimize fuel consumption while reducing operational costs. This not only contributes to the economic feasibility but also reduces environmental impact, which is becoming increasingly important in modern drilling projects.

Our solutions are also suitable for industries beyond oil and gas production, such as geothermal drilling and carbon capture. In the geothermal industry, our systems are used for deep drilling to access geothermal energy sources, providing access to hot underground water or steam for power generation and heating. In CO₂ injection (carbon capture), drilling is necessary to inject carbon dioxide into underground formations and remove it from the atmosphere.

Thus, Zeppelin Power Systems provides customized solutions that address the specific challenges of onshore drilling, offering high efficiency and sustainability.

Zeppelin Power Systems industries

Customized solutions for your drilling projects

Mobile drilling rigs and geothermal drilling impose high demands on flexibility and reliability, as they often operate in challenging and remote environments. Zeppelin Power Systems offers customized drive solutions specifically developed to meet the challenges in the drilling sector.

Zeppelin Power Systems Solutions for Oil & Gas

Comprehensive solution concepts for your drilling project

Show all Solutions for Oil & GasHigh-performance engines and generators for demanding drilling operations

Show all Products for Oil & GasZeppelin Power Systems Resources for Oil & Gas

Brochures available for Download

Show all Resources for Oil & Gas

Well Service Engines

You can find more information about our Well Service engines in the brochure

Flare Gas Solutions

You can find more information about our flare gas solutions in the brochure

Cat Transmissions

You can find more information about our transmissions in the brochure

Drive Trains

You can find more information about our drive trains in the flyer

Zeppelin Power Systems Portfolio

Explore more from the Zeppelin Power Systems portfolio

Power & Heat

Rail

© 2025 Zeppelin Power Systems GmbH