Energy and drive solutions for offshore platforms

Rely on Cat power for upstream and midstream applications on your drilling rig

Offshore drilling can often reach depths of thousands of meters. At such depths, reliable drive and energy systems are essential for the efficient and safe operation of drilling rigs. Our robust and certified Cat gensets are specifically designed for the demanding and often hazardous conditions in the offshore sector, offering maximum efficiency, longevity, and safety. Whether for drilling, production, or transportation, Cat power ensures that your facility remains operational around the clock, even in the most extreme environments.

With our customized products and services, we enhance reliability on drilling rigs and provide the right solution for every challenge.

Available for you 24/7

Germany

International

Key benefits for your organization

High operating hours without downtime

Cat engines and gensets are extremely reliable and designed for long operating hours without downtime. This minimizes maintenance requirements, which is especially critical for remote offshore platforms.

Explosion protection and safety

Drilling rigs are located in hazardous environments where explosive gases may be present. Our drive systems meet the strict requirements for explosion protection, such as the ATEX directive (EU) or IECEx standards.

Mobility and modularity

Our gensets are modular in design and easily transportable, making them flexible for use on the platform. This facilitates the replacement of faulty parts and transportation by ship or helicopter.

Easy maintenance and remote monitoring

The robust construction, modular design, absence of coolant in the engine block, and minimal piping on the engine ensure easy maintenance. Additionally, remote monitoring systems support proactive maintenance planning by alerting early to potential issues.

Zeppelin Power Systems Solutions for Oil & Gas

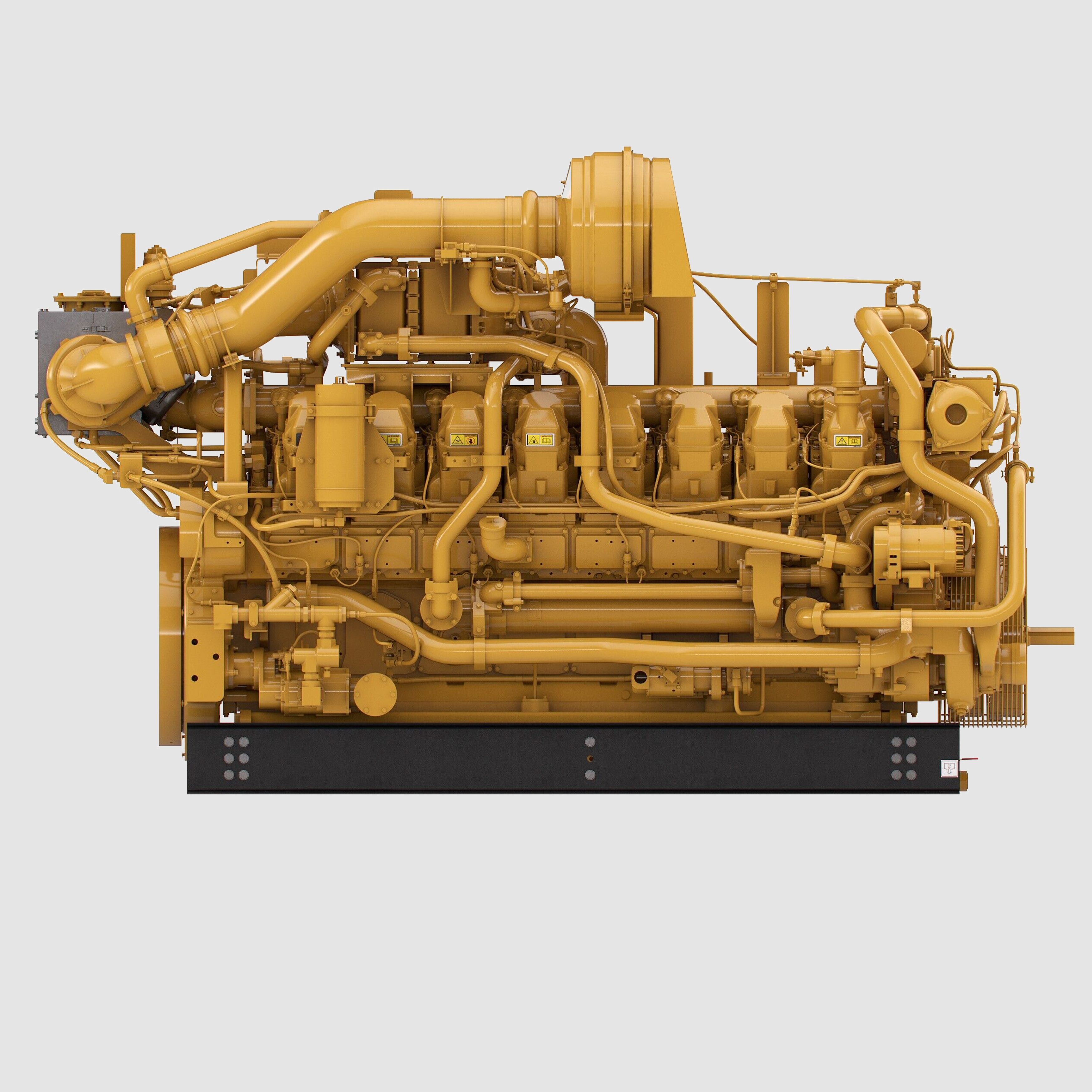

Customized drive systems for drilling and production on offshore platforms

For drilling rigs, we provide customized drive systems to optimally support the critical processes of drilling, production, and compression. Our engines are individually configured and tailored to conditions such as production volume, temperature, and pressure.

Optimal drive solutions for deep drilling

Offshore drilling technology is highly energy-intensive and requires powerful drive systems. Our Cat offshore gensets provide the necessary power to drive drill strings and top-drive systems required for deep drilling. They are capable of delivering constant power and high torque to efficiently operate the drilling equipment even under challenging conditions. Additionally, they are used to power mud pumps, which pump drilling fluid (mud) into the wellbore and transport cuttings away.

Our Caterpillar engines support the smooth execution of drilling operations, contributing to increased operational safety and productivity.

Optimal power supply for your production facilities

Cat drive systems are essential for powering production and submersible pumps that bring crude oil from the depths of the reservoir to the surface. To ensure an uninterrupted flow of oil and gas, these systems must operate with the highest reliability and withstand the extreme offshore conditions. Cat engines provide the necessary power and durability to efficiently operate these pumps, even under harsh environmental conditions and fluctuating loads.

Efficient gas compressors with Cat engines

In gas production, our engines are used to power gas compressors that compress the produced natural gas and prepare it for transport through pipelines. Thanks to innovative combustion technologies, Cat gas engines also have an increased tolerance regarding gas quality and are suitable for burning almost all types of gas.

Do you have questions about drive solutions for drilling and production? We are happy to advise you.

Master the challenges of the deep sea with Cat engines for demanding well service operations

Well services on offshore platforms pose a greater challenge than onshore operations due to the additional water depth. In addition to the drilling depth, the often significant water depth must also be overcome, requiring more powerful machines and drive systems. With our Cat products, you can successfully tackle complex and demanding well service operations even on the seabed.

Wellbore repair and cleaning

Under high-pressure conditions and temperatures near freezing, our Caterpillar products are the first choice as drives for wellbore cleaning equipment. This allows them to efficiently remove deposits and sand, restoring production flow. Additionally, Cat generator sets are used in pumps that inject specialized cleaning fluids under increased pressure into the wellbore to eliminate blockages and ensure efficient repair.

Challenges of fracking on the seabed

Offshore fracking places high demands on drive systems and the entire fluid management process to ensure safe and efficient production. The extreme cold at the seabed affects the flow properties of the fracking fluids, which become more viscous under the deep and cold conditions. Additionally, antifreeze agents are added to the fluids to ensure they can penetrate deep into the earth's layers and perform effectively, even at extremely low temperatures. Our gensets are specifically adapted to meet these requirements, providing the additional power needed to carry out wellbore stimulation efficiently.

With our powerful products, we find a solution for every complex offshore requirement and are happy to provide personalized advice.

Zeppelin Power Systems Solutions for Oil & Gas

Mobile and stationary container solutions for offshore operations

ATEX-certified container solutions for offshore use

Our ATEX-certified container solutions from Zeppelin Power Systems provide secure, flexible protection for critical drive and power supply systems under extreme offshore conditions. These robust containers reliably protect control systems, energy units, and safety-critical components from external influences. Configurable as mobile or stationary units, they ensure maximum operational safety and continuous performance for specific offshore applications – supported by our tailored consulting and service.

Energy & drive: Complete solutions for offshore drilling rigs

Our complete solutions for offshore drilling rigs cover a wide range of energy and drive systems. We offer customized container solutions for the safe operation of gas and power generators. In the drilling sector, our robust drives and energy systems ensure reliable operation and high efficiency during the drilling process. For production, we provide powerful systems that secure the power supply. Flare gas is utilized through our power and heat generation technologies to reduce emissions. Our gensets for compressors ensure optimal gas processing, while our well service solutions efficiently support the maintenance and operation of wells.

Planning

- Consulting

- Concept Development

- Project Engineering

Engineering

- Electrical & Installation Planning

- Process Technology

- CAD-based Planning

Project Management

- Site Management

- Technical Procurement

- Quality Assurance

Plant Construction

- Electrical Installation

- Assembly

- Commissioning and Test Run

Service

- Maintenance

- Routine Servicing

- Troubleshooting Service

Zeppelin Power Systems Solutions for Oil & Gas

Offshore solutions for the efficient and sustainable use of flare gas

Flare gas gensets for sustainable energy on offshore platforms

In offshore oil production, flare gas is generated, which can be used as fuel for gas gensets to produce power and heat. Our gensets, specifically designed for offshore environments, can be easily installed near the flare stack, where they provide energy for essential applications such as water injection pumps or power supply to accommodations (camp power). Additionally, flare gas can be efficiently used for heat generation, such as for heating crude oil, sustainably meeting the energy needs on offshore platforms and reducing emissions.

An overview of the different offshore platforms

Offshore platforms serve as central production facilities from which oil and gas are extracted, processed, and transported. Drilling rigs come in various forms.

Fixed Platforms

Fixed platforms are anchored to the seabed, typically using steel or concrete supports that carry the platform's deck. They are used in relatively shallow waters (up to about 500 meters). The platform houses drilling equipment, production facilities, and accommodations for the personnel.

Semi-submersible Platforms

In deeper waters (up to 3,000 meters), semi-submersible platforms are anchored or fixed using dynamic positioning systems and partially float in the water. They are more stable than floating platforms because a large portion of the structure is submerged beneath the water's surface, making them less susceptible to wave movements.

Drillships

Specialized vessels are also used for deep-sea drilling, equipped with advanced systems to maintain their position. They can easily move between different drilling sites and are deployed in extremely deep waters. These ships are designed to operate in challenging offshore environments and are equipped with state-of-the-art drilling and positioning technologies.

(Tension Leg Platforms)

These platforms are anchored by vertical tendons (tension legs) that are fixed to anchor points on the seabed. They provide stability in deep waters (over 1,000 meters) and feature a flexible design that minimizes movement caused by sea currents or waves.

FPSO-Vessels (Floating Production, Storage, and Offloading)

These are floating platforms used for production, storage, and transportation of oil and gas. Crude oil is stored in tanks on the ship until it is picked up by tankers or transported through pipelines. FPSOs (Floating Production, Storage, and Offloading units) are flexible and can be easily moved from one oil field to another.

Jack-up-Rigs

Jack-up rigs have legs that are lowered into the seabed, while the deck remains above the water's surface. They are used in shallow waters (up to 150 meters deep) and are primarily employed for exploration and drilling operations.

Zeppelin Power Systems industries

Customized drive solutions for FPSO, fracking, and more

For demanding offshore applications, Zeppelin Power Systems provides customized Cat engine and generator solutions. The resilient drive systems ensure reliable operation even under the toughest conditions – whether on floating production units (FPSO), mobile drilling rigs, or fixed offshore platforms. Cat gensets ensure the required power supply and operational stability in offshore wind farms. Precise control and reliable performance – essential for smooth offshore operations – are also hallmarks of our solutions in wireline and slickline service work.

Zeppelin Power Systems Solutions for Oil & Gas

Customized complete solutions for drilling projects in the oil and gas industry

Show all Solutions for Oil & GasZeppelin Power Systems Products For Oil & Gas

Powerful Cat products for the offshore industry

Show all Products for Oil & GasZeppelin Power Systems Resources for Oil & Gas

Brochures and certificates for Oil & Gas available for download

Show all Resources for Oil & Gas

High-Performance Drives for Fracking Trucks – Precision & Efficiency | Zeppelin Power Systems-Engine Ratings Guide

Engine Ratings Guide

High-Performance Drives for Fracking Trucks – Precision & Efficiency | Zeppelin Power Systems-You can find more information about our Well Services in the brochure

You can find more information about our Well Services in the brochure

Zeppelin Power Systems Portfolio

Explore more from the Zeppelin Power Systems portfolio

Power & Heat

Rail

© 2025 Zeppelin Power Systems GmbH