How you can benefit from flare gas

Utilize flare gas instead of burning: Maximum energy, minimal emissions

Zeppelin Power Systems offers specialized solutions in the flare gas sector to efficiently utilize flare gas and reduce emissions. A key approach is the conversion of flare gas into electricity, where the typically flared gas is used in gas generators or gas engines for power generation. Notably, the flexible Cat engine technology allows for the efficient utilization of various types of gas, including low-quality gases.

As a full-service partner, we handle the entire design process, including gas and amortization analysis. Benefit from our experience and expertise in every phase of your project, from planning and successful implementation to after-sales service.

Available for you 24/7

Germany

International

Key benefits for your organization

Provision of additional energy

Flare gas can be used for power and heat generation, providing a cost-effective additional energy source. This leads to an efficient use of a previously unused energy carrier while simultaneously reducing reliance on other fossil fuels.

Environmental protection

By converting flare gas into energy instead of flaring it, you minimize CO₂ and methane emissions and actively contribute to a more sustainable future. This not only improves your company's environmental footprint but also helps meet stringent environmental regulations.

Cost efficiency

Investing in flare gas utilization systems pays off quickly. Thanks to savings on energy costs, your company gains financial flexibility and benefits from lower operational costs.

Reliability

Our robust Cat solutions and intelligent monitoring systems guarantee maximum uptime and minimize the risk of failures. Your company can rely on a reliable and continuous power supply – even in demanding environments.

Zeppelin Power Systems Solutions for Oil & Gas

Flare gas – An untapped resource with great potential

Flare gas is produced wherever oil is extracted. Zeppelin Power Systems offers customized solutions to efficiently utilize this valuable resource for energy generation.

Utilize your flare gas for efficient power and heat generation

Instead of simply releasing flare gas into the atmosphere, it can be used as fuel for gensets to generate electricity. Our gas gensets, which we also offer in explosion-proof overpressure containers, can be easily installed and connected to the flare stack. The generated energy can be used directly on-site, for example, to power water injection pumps or camp power.

Our technology also allows for the efficient use of flare gas for heat generation, such as heating crude oil. This provides independence from fluctuating fuel prices. Investments in this technology pay off quickly and ultimately increase both your efficiency and profits. Furthermore, you reduce your CO₂ footprint and actively contribute to meeting the "Zero Flaring" commitments, which will be mandatory from 2030.

What’s particularly impressive is the versatility of our Cat gensets, which can operate on various types of gas, including low-quality gases like flare gas. This is especially important, as the composition of flare gas often varies.

Zeppelin Power Systems is your partner for the sustainable and economical use of flare gas – let us work together to unlock the potential of this resource.

Zeppelin Power Systems Solutions for Oil & Gas

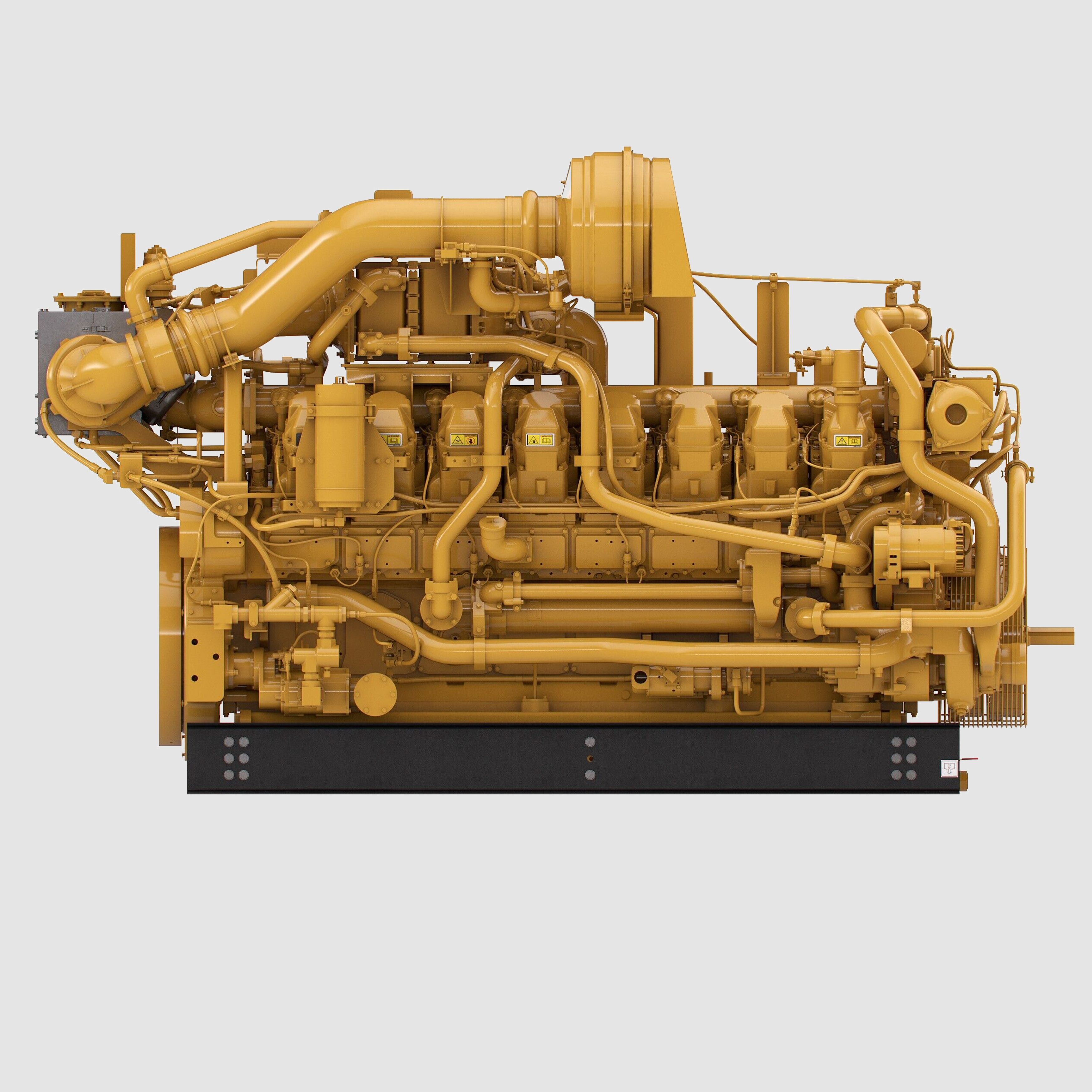

Powerful and certified Cat engines for your flare gas application

Cat products for every power requirement

At the core of our technology are robust, durable, and ATEX-approved Caterpillar engines and gensets. Our product portfolio includes more compact models such as the Cat G3406/G3412 with 160/305 ekW gross and the Cat G3508/G3512 with 480/725 ekW gross, which can process untreated gas with a methane number of up to 30. For higher power requirements, we offer more powerful units such as the Cat G3516A (975 ekW gross), the Cat G3520E (1,995 ekW gross), and the Cat G3600-A4 series (1,330 to 3,500 ekW gross).

Precise engine customization through complete gas analysis

Our software "Gas Engine Rating Pro" (GERP) from Caterpillar enables precise customization of engines to the specific gas characteristics on site, optimizing the performance and efficiency of the systems. GERP analyzes the gas composition and calculates the ideal operating parameters for the engine, resulting in optimal energy output and higher reliability. This accurate tuning minimizes wear and ensures a longer lifespan for the engines.

Maximum safety through ATEX-compliant engines

Our flare gas gensets can be flexibly integrated as standalone units in both onshore and offshore installations, with various certifications available, such as API, ASME, U-Stamp, or international standards like DNV-GL. For explosion-hazardous areas, ATEX and IECEx-compliant engines are available.

Do you have questions about our products? We are happy to advise you.

Zeppelin Power Systems Solutions for Oil & Gas

Compact container solutions for flare gas utilization

Container solutions with ATEX certification for flare gas utilization

Zeppelin Power Systems offers customized, explosion-proof container solutions for the efficient utilization of flare gas in the oil and gas industry.

These compact and flexible units enable the safe conversion of flare gas into electricity and heat, even in explosion-hazardous areas. Thanks to their mobility, quick commissioning, and modular design, the containers can be easily deployed at changing locations. Additionally, they are user-friendly for maintenance and designed for continuous operation under demanding conditions.

From analysis to power generation: Complete solutions for your flare gas.

From analysis to power generation, with our Cat gensets, we develop flare gas solutions tailored to your specific requirements, while meeting the highest standards in terms of cost-effectiveness, reliability, and environmental protection. With our technology, you not only contribute to reducing greenhouse gas emissions but also unlock new revenue streams from previously unused resources.

Planning

- Consulting

- Concept Development

- Project Engineering

Engineering

- Electrical & Installation Planning

- Process Technology

- CAD-based Planning

Project Management

- Site Management

- Technical Procurement

- Quality Assurance

Plant Construction

- Electrical Installation

- Assembly

- Commissioning and Test Run

Service

- Maintenance

- Routine Servicing

- Troubleshooting Service

Flare gas is a valuable resource for the oil and gas industry

Flare gas, a byproduct of oil extraction, has long been considered waste and simply burned off. However, with increasing environmental awareness and stricter regulations, the utilization of flare gas is gaining greater importance. Approximately 5% of the global gas demand is flared worldwide, equating to a market value of around $40 billion – approximately 2.4 million barrels of oil per day. By converting this gas into usable energy, companies can not only reduce their CO₂ emissions but also lower their operational costs.

Types of Flare Gas and Utilization Technologies

Flare gas can broadly be classified into associated gas, vent gas, and produced water vapor, with each type having specific characteristics that influence the choice of utilization technology. A crucial step in the preparation of flare gas is the use of coalescing filters, which remove liquids and impurities such as water or oil droplets from the gas stream. This is particularly important because the composition of flare gas can vary significantly, and clean gas is essential for efficient utilization. Gas turbines, combustion engines, and steam turbines benefit from this gas conditioning, as it enhances the performance and longevity of the equipment. The choice of the appropriate technology ultimately depends on factors such as gas composition, flow rate, and the desired energy output, with the prior filtration through the coalescing filter playing a key role.

Benefits of flare gas utilization

- Environmental benefits: Reduction of greenhouse gas emissions, improvement of air quality, and meeting stringent environmental standards.

- Economic benefits: Lower operating costs through efficient energy use, potential revenue from the sale of surplus energy.

- Compliance: Meeting regulatory requirements and participating in global initiatives such as "Zero Routine Flaring by 2030."

Challenges and solutions

The utilization of flare gas is not without challenges. Fluctuating gas compositions, remote locations, and harsh environmental conditions complicate implementation. However, innovative solutions such as modular flare gas utilization systems and digital technologies for monitoring and optimizing processes help to overcome these challenges.

Zeppelin Power Systems industries

Utilize flare gas: Efficient energy for your drilling rigs

Mobile and stationary drilling rigs require reliable and efficient energy systems, especially in demanding and remote environments. Zeppelin Power Systems' flare gas solution is particularly relevant here, as it converts unused flare gas into usable energy. This innovative technology not only increases efficiency but also reduces emissions and operating costs. As a result, it significantly contributes to a more sustainable power supply on mobile drilling rigs and offshore platforms.

Zeppelin Power Systems Solutions for Oil & Gas

Complete solutions from a single source for your drilling project from Zeppelin Power Systems

Show all Solutions for Oil & GasZeppelin Power Systems Products For Oil & Gas

Utilize unused gas: Cat engines for sustainable energy

Show all Products for Oil & GasZeppelin Power Systems Resources for Oil & Gas

Brochures available for Download

Show all Resources for Oil & Gas

Well Service Engines

You can find more information about our Well Service engines in the brochure

Flare Gas Solutions

You can find more information about our flare gas solutions in the brochure

Cat Transmissions

You can find more information about our transmissions in the brochure

Drive Trains

You can find more information about our drive trains in the flyer

Zeppelin Power Systems Portfolio

Explore more from the Zeppelin Power Systems portfolio

Power & Heat

Rail

© 2025 Zeppelin Power Systems GmbH