Container solutions for the oil and gas industry: Flexible, robust, and customized

Versatile containers for onshore and offshore applications

Our specially developed container solutions provide optimal protection and efficiency for gensets and engines in extreme offshore and onshore environments. Whether for use on oil rigs or in the harsh conditions of oil fields, our containers ensure reliable safety, durability, and maximum protection against weather, corrosion, and mechanical stresses. They are custom-tailored to the specific requirements and operational conditions of our customers.

The versatility of our container technology is demonstrated by its wide range of applications. Whether for flexible transport or permanent protection, our container solutions can be adapted for nearly any application, from gas compression and drilling drives to well service. We also offer special ATEX-certified containers for use in explosive environments.

Available for you 24/7

Germany

International

Key benefits for your organization

High flexibility and mobility

Thanks to their compact design, the container solutions are ideal for transportation, even in hard-to-reach regions or offshore areas. They can be easily moved by helicopter, truck, or ship, offering maximum flexibility in logistics.

Customizable

We offer each of our solutions in container form, whether for compressor units, power supply, or specialized applications such as well service. Depending on customer requirements, we provide both open and enclosed container units.

Quick installation

The modular design of the containers allows for quick and cost-effective installation. Their maintenance-friendly construction reduces downtime and ensures efficient operation, ultimately lowering operating costs and increasing productivity.

Containers for explosion-proof environments

We also offer all drives in overpressure containers that meet the highest safety standards. Our robust and energy-efficient systems can reliably operate in ATEX zones.

Zeppelin Power Systems Solutions for Oil & Gas

Stationary containers for demanding applications in onshore and offshore environments

Stationary container solutions form the backbone of many facilities in the oil and gas industry. They are used wherever permanent, high-performance, and secure infrastructures are required.

Our container solutions provide a flexible and reliable way to securely house critical drive and power supply systems while protecting them from external influences.

Our large 20- or 40-foot DIN containers are used as so-called power houses. These house our powerful Cat drive systems and gensets, which are essential for the continuous operation of drilling rigs and other energy-intensive processes. The robust construction of these containers ensures reliable protection of valuable equipment from harsh environmental conditions.

Furthermore, our stationary containers play an important role, for example, in gas compression. Compressor units responsible for compressing and transporting gas through pipelines or storing it in underground storage are often housed in containers. These not only protect the sensitive equipment but also allow for efficient maintenance and monitoring of the systems.

Explosion-proof container solutions

Our ATEX-certified containers are used in explosive areas. These highly specialized units are equipped with overpressure systems that prevent the ingress of explosive gases. Special door constructions with safety locks and separate air ducts for intake air and exhaust gases are standard features.

DNV-certified containers for offshore applications

Stationary container solutions also play a crucial role on offshore platforms. These containers must withstand extreme conditions while meeting the highest safety standards. They are saltwater-resistant, DNV-certified, and equipped with spill containment systems. These containers often house critical equipment such as control systems, power supply units, or safety devices.

If you would like to learn more about our container solutions, we are happy to advise you.

Zeppelin Power Systems Solutions for Oil & Gas

Mobile container solutions for maximum flexibility on the oil field or drilling platform

Our mobile container solutions impress with high flexibility and versatility. They provide space for complete drilling rigs or drilling drives, are mounted on special oilfield frames, and can be quickly transported to new deployment locations – a major advantage for frequently changing drilling sites. The containers are designed to withstand harsh transport conditions while optimally protecting the sensitive drilling equipment.

Compact containers for offshore use

For highly mobile applications such as wireline or slickline units in well service, we offer compact containers. Thanks to their lightweight design and equipped with smaller engines, these units are ideally suited for helicopter transport between offshore platforms. They provide maximum mobility and flexibility without compromising on performance.

Custom container enclosures

We offer customized enclosures tailored to different requirements. Robust containers with solid walls provide ideal protection in extreme environments such as offshore or desert regions. For mobile applications and onshore projects, lighter enclosures made of truck tarpaulin are available, offering flexibility and ease of transport.

Our offshore containers are saltwater-resistant and DNV-certified, while our ATEX-certified enclosures are suitable for use in explosive environments. This allows Zeppelin Power Systems to provide flexible solutions for any operational environment and application.

Are you looking for a customized container solution for your drives? We would be happy to advise you.

Comprehensive container solutions: From planning to implementation

The flexibility of our container solutions allows us to find the right solution for almost any application, whether for mobile drilling drives, offshore power supply, or specialized applications such as wellbore cleaning equipment. We provide extensive expertise in planning and implementing these solutions and work closely with our clients to develop customized systems that meet the requirements for safety, mobility, and efficiency.

Planning

- Consulting

- Concept Development

- Project Engineering

Engineering

- Electrical & Installation Planning

- Process Technology

- CAD-based Planning

Project Management

- Site Management

- Technical Procurement

- Quality Assurance

Plant Construction

- Electrical Installation

- Assembly

- Commissioning and Test Run

Service

- Maintenance

- Routine Servicing

- Troubleshooting Service

ATEX-certified containers: Maximum safety for your applications

A particularly demanding area of container technology offered by Zeppelin Power Systems is explosion-proof or ATEX-certified containers. These are primarily used in applications with gas engines, as there are few ATEX-certified engines in this area. The certifications vary by region and application: While CSA (Canada) and NEC (USA) primarily focus on electrical aspects, ATEX (Europe) and IECEx (Asia) also consider surface temperatures, as some gases can ignite on hot surfaces. These certifications aim to maximize the safety of workers in hazardous, explosive environments.

This is how ATEX-certified containers work

In an ATEX-certified container, an overpressure is created to prevent the ingress of flammable substances. Special door constructions with safety locks ensure that the overpressure is maintained. Additionally, both the intake air and exhaust gases must be routed to safe areas outside the ATEX zone, often requiring long piping.

The definition of ATEX zones is the responsibility of the operator and is divided into Zones 0, 1, and 2. Zone 0, typically the well itself, is considered permanently hazardous and must not contain flammable components. Zone 1 extends, for example, within a five-meter radius and poses a high explosion risk, while Zone 2 starts, for example, at seven meters and is only considered hazardous in the event of an accident or failure. This clear zoning primarily determines the placement of equipment and personnel.

The complexity of safety requirements is particularly evident in offshore operations. Here, the entire platform is considered a potentially hazardous area, except for specific "Safe Areas." These areas, which are under overpressure, provide safe spaces for the daily activities of personnel. Access to offshore drilling rigs is therefore strictly regulated and requires special safety training.

Zeppelin Power Systems industries

From fracking to FPSO: Our container solutions for the entire oil and gas industry

Zeppelin Power Systems offers mobile and stationary container solutions that can be flexibly used in various industry applications within the oil and gas sector. Whether on offshore platforms, for fracking trucks, mobile drilling rigs, or FPSO units, our container solutions are designed for optimal use under demanding conditions. They not only provide protection and transportation for drive and energy systems but also enable quick installation and maintenance on-site, significantly increasing the efficiency and operational reliability of the plants.

Zeppelin Power Systems Solutions for Oil & Gas

Complete solutions for your drilling project from Zeppelin Power Systems

Show all Solutions for Oil & GasZeppelin Power Systems Products For Oil & Gas

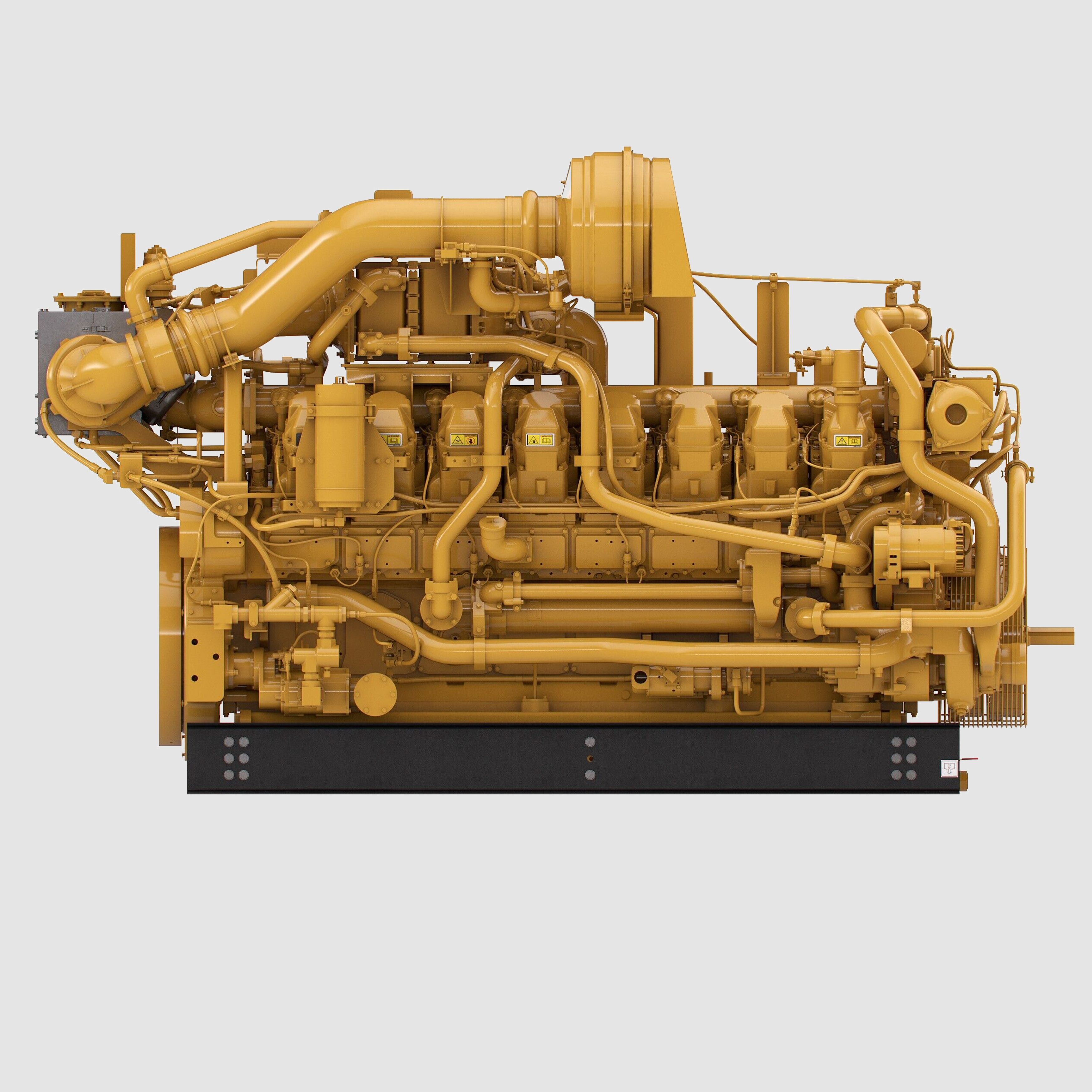

From drilling to production: Caterpillar products in mobile containers

Show all Products for Oil & GasCaterpillar products are ideally suited for use in mobile and stationary containers. Thanks to their robust design, our containers provide optimal protection and security for sensitive drive and energy systems. Additionally, the modular construction allows for flexible adaptation to various applications, making them versatile and efficient for a wide range of uses.

Zeppelin Power Systems Resources for Oil & Gas

Brochures available for Download

Show all Resources for Oil & Gas

Well Service Engines

You can find more information about our Well Service engines in the brochure

Flare Gas Solutions

You can find more information about our flare gas solutions in the brochure

Cat Transmissions

You can find more information about our transmissions in the brochure

Drive Trains

You can find more information about our drive trains in the flyer

Zeppelin Power Systems Portfolio

Explore more from the Zeppelin Power Systems portfolio

Power & Heat

Rail

© 2025 Zeppelin Power Systems GmbH