Solutions for sustainable CO₂ capture

Drive technology for carbon capture

Carbon capture is a process in which CO₂ is captured from the atmosphere or directly at the emission source in order to reduce greenhouse gas emissions. Our high-quality Cat gas engines are used in compression systems that efficiently compress the CO₂ and thus optimally prepare it for transportation or storage.

With our products and our extensive experience, we are happy to support you in this important step of efficient and sustainable CO₂ capture.

Planning

- Consulting

- Concept Development

- Project Engineering

Engineering

- Electrical & Installation Planning

- Process Technology

- CAD-based Planning

Project Management

- Site Management

- Technical Procurement

- Quality Assurance

Plant Construction

- Electrical Installation

- Assembly

- Commissioning and Test Run

Service

- Maintenance

- Routine Servicing

- Troubleshooting Service

Zeppelin Power Systems Solutions for Oil & Gas

From concept to implementation - our solutions for carbon capture

Show all Solutions for Oil & Gas

Gas Compression

Our gas compression solutions are suitable for the requirements of carbon capture processes. They reliably compress CO₂ to prepare it for transportation or storage.

Container Solutions

Our container solutions provide protection for drive systems and ensure greater flexibility and mobility.

Key benefits for your organization

Reliable performance

Our compression solutions for CO2 separation deliver reliable performance even in harsh temperatures and difficult environments. The robust design of our products ensures constant and trouble-free operation.

Reduction of emissions

Carbon capture technology enables the capture of CO₂, which significantly reduces emissions from sectors that are difficult to decarbonize.

Flexible use of different gases

Cat gas engines have a low compression ratio so that they can also burn low-grade gases efficiently.

Solutions from one source

With us, you benefit from seamlessly coordinated systems and a central point of contact. As a result, implementation is quick, smooth and uncomplicated.

Zeppelin Power Systems Products For Oil & Gas

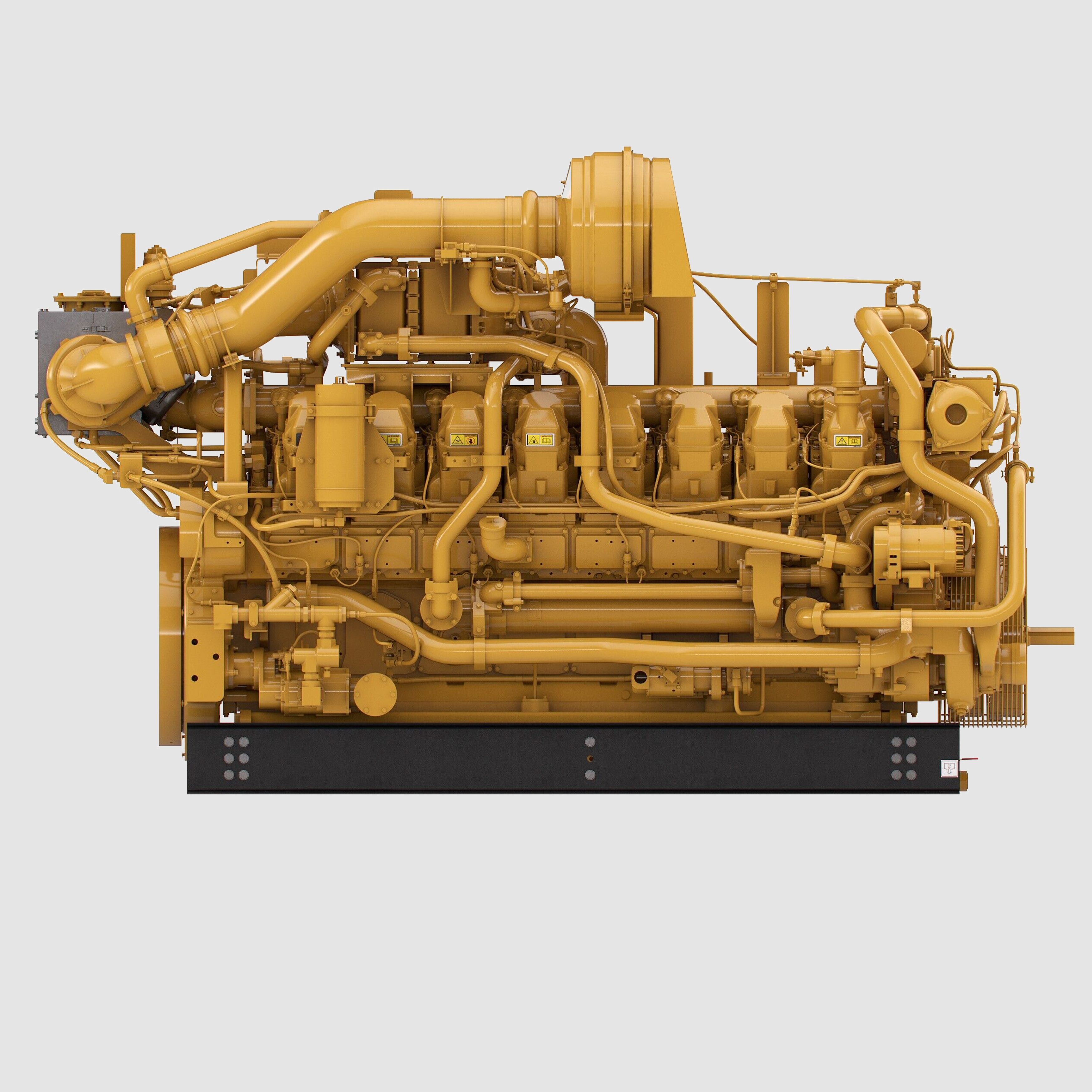

Cat gas engines for the compression of CO₂

Compression plants play an important role after the capture of CO₂ in order to compress the CO₂ and prepare it for transportation or storage. The use of such plants is necessary to reduce the CO₂ to a manageable volume and convert it to the desired state.

In many cases, the compressed CO₂ is injected into geological formations such as empty oil or gas fields, deep saltwater aquifers or basaltic rock layers. The high pressures achieved by the compression are important for forcing the CO₂ safely into these deep geological layers.

High efficiency and low fuel consumption

For compression systems, we offer Cat gas engines from the G3300, G3400, G3500, G3600 and CG137 series. These are ideal for compression. The engines also feature integrated ADEM™ A4 technology, which enables precise fuel control.

The engines are also characterized by outstanding mechanical efficiency (up to 44%) and low fuel consumption. They can be operated at ambient temperatures of +45°C and an altitude of 900 m above sea level without any loss of power and are also ready for use at low pressures (0.07 to 3.1 bar).

The three main stages in the carbon capture process

Carbon capture is a technology that aims to capture carbon dioxide (CO₂) from industrial emissions or the atmosphere in order to reduce the concentration of CO₂ in the air. This is particularly relevant in sectors where emissions are difficult to avoid. Carbon capture technology plays an important role in achieving net zero emission targets and actively reducing CO₂ that has already been emitted.

The carbon capture process comprises three main stages: Capture, transportation and storage or utilization. In the capture phase, the CO₂ is removed directly at the emission source or from the air. Different processes are used depending on the application. In the post-combustion process, the CO₂ is filtered out of the exhaust gases after combustion, often with the help of chemical solvents. In the pre-combustion process, the fuel is converted into CO₂ and hydrogen before combustion, whereby the CO₂ is separated and the hydrogen is used to generate energy. A third option, oxyfuel combustion, uses pure oxygen to produce almost exclusively CO₂ and water vapor, which facilitates capture.

After capture, the CO₂ is compressed and transported to a storage site via pipelines, for example. Transportation in a supercritical state (at high pressure) reduces the volume of CO₂, which increases efficiency and safety. In the final phase, storage or utilization, the CO₂ is either stored permanently in geological formations or used for industrial processes.

Carbon capture offers great opportunities to reduce emissions from sectors that are difficult to reduce and at the same time lower the concentration of CO₂ in the atmosphere. However, the technology is still under development and is associated with challenges such as high costs, energy consumption and safe long-term storage.

Zeppelin Power Systems Solutions for Oil & Gas

Your specialist for drive technology in the oil & gas industry

Show all Solutions for Oil & GasZeppelin Power Systems Products For Oil & Gas

Robustly built for the demanding oil & gas industry

Show all Products for Oil & GasZeppelin Power Systems Resources for Oil & Gas

Brochures and certificates for Oil & Gas available for download

Show all Resources for Oil & Gas

High-Performance Drives for Fracking Trucks – Precision & Efficiency | Zeppelin Power Systems-Engine Ratings Guide

Engine Ratings Guide

High-Performance Drives for Fracking Trucks – Precision & Efficiency | Zeppelin Power Systems-You can find more information about our Well Services in the brochure

You can find more information about our Well Services in the brochure

Zeppelin Power Systems Portfolio

Explore more from the Zeppelin Power Systems portfolio

Power & Heat

Rail

© 2025 Zeppelin Power Systems GmbH