High-quality products from Optimarin for effective ballast water treatment

Optimarin BWTS components combine top performance and reliability

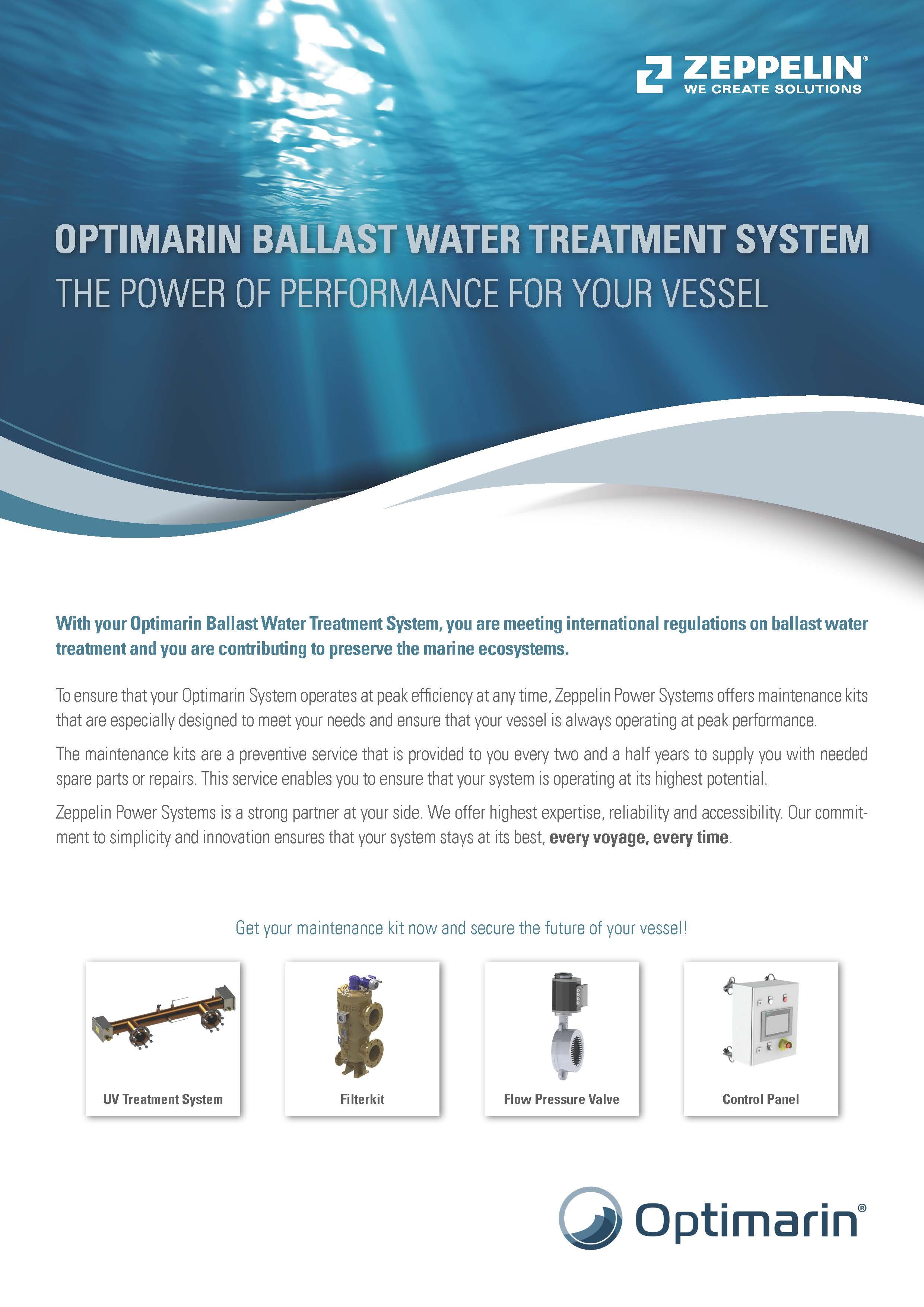

Our product components from Optimarin include powerful UV systems, efficient filters, robust backflush pumps, precise pressure control valves, and user-friendly control panels. Innovative technologies ensure effective removal of organisms and particles, high flow rates, and reliable performance with minimal maintenance. Our ballast water treatment systems provide sustainable and efficient ballast water treatment that meets the highest environmental standards.

Available for you 24/7

Germany

International

Filters for optimal water quality and efficient flow rates

In our ballast water treatment system, the filter plays a crucial role in removing particles from seawater during the ballast or stripping processes. The filter fabric effectively captures larger particles and prevents them from entering the system.

Key Features of Our Filter Technology

Our filter is designed to remove larger particles and organisms from seawater, ensuring optimal water quality.

Minimal pressure loss: With a pressure loss of only 0.1 to 0.5 BAR, our filter ensures efficient flow rates without significant energy consumption.

Bypass function: During ballast water discharge, the filter is intelligently bypassed, allowing for smooth and quick water discharge.

Automatic self-cleaning: Our filter is equipped with an automatic self-cleaning function. By reversing the flow direction and backflushing untreated water into the sea, continuous filter performance is ensured.

Filter types

Optimarin uses high-quality filters in their ballast water treatment systems (BWTS) to ensure the efficiency and reliability of particle removal from seawater:

Filtrex Filters: A basket-type filter that can filter particles down to a size of 20 microns. This filter is known for its high filtration efficiency and robustness.

If you have any questions about our filters, we are happy to assist you with our comprehensive consulting services.

Optimal filter performance with Optimarin backflush pumps

The backflush pump from Optimarin is an essential component of the ballast water treatment system. It is used to regularly clean the filtration system and prevent blockages. The pump ensures that the filter is backflushed under high pressure, removing accumulated dirt particles, sediments, and microorganisms. This keeps the filtration system efficient and operational, contributing to the overall performance of the ballast water treatment system. Backflush water does not need to be treated according to regulations.

Robust and efficient pump technology

The backflush pump is a centrifugal pump with an electric motor. It is connected to the overboard line for filter backflushing and contributes to more efficient filter cleaning. It is automatically activated when a filter backflush is required.

Would you like to learn more about our backflush pump technology? We are happy to provide you with further information.

Powerful UV systems for optimal ballast water treatment

Our systems use strong UV light to efficiently eliminate organisms in ballast water. Each chamber treats up to 167 m³/h of water. By installing the chambers in parallel, virtually unlimited capacities are possible, ensuring maximum efficiency and performance.

Key Features of Our UV Technology

- High-performance UV lamps efficiently inactivate organisms, bacteria, and pathogens in ballast water, ensuring excellent treatment results.

- Das The system consists of one or more UV chambers installed in parallel. Each chamber is made from a single CuNi Fer 90/10 DN150 pipe with a robust wall thickness of 3 mm.

- Each UV chamber can effectively treat up to 167 m³/h of ballast water, thanks to the implementation of a high-performance UV lamp. With a maximum UV lamp power of 35 kW, our system delivers exceptional performance.

- The chambers are equipped with UV and temperature sensors to ensure precise monitoring and control, enabling real-time data acquisition and adjustments.

- Our system utilizes a standardized UV chamber design, which can be installed in parallel on a single rack. This configuration allows for higher flow rates and enhances the scalability of the system..

- Our UV system is designed for minimal maintenance requirements and ease of operation. It does not require chemical cleaning and has no moving parts, ensuring hassle-free usage.

- Each chamber can handle a maximum flow rate of 167 m³/h in all modes, ensuring efficient treatment performance.

- In IMO mode, no holding time is required, allowing continuous flow and operation. In USCG mode, the holding time is reduced to 24 hours.

Would you like to learn more? We are happy to assist you.

Precise pressure control valves for your ballast water treatment system

Our pressure control valves regulate the pressure of your ballast water treatment system with exceptional reliability and efficiency, contributing to the overall efficiency and safety of the system. With electric flow-pressure-valve technology, you experience the latest advancements in valve control, technology, and acoustics.

Key Features of Our Pressure Control Valves

- The electric Flow Pressure Valves (FPV) feature a compact design with a diameter of DN350 at only 193 mm, allowing for efficient use of space.

- With a weight of just 130 kg for DN350, the FPVs are very lightweight, reducing the overall weight of the system.

- The valves consist of a shut-off flap with a rubber seat and a bronze-aluminum disc. The flow element is made of stainless steel, ensuring durability and reliable performance.

- The FPV is electrically operated, providing precise control and reliable operation.

- The actuator is designed with a fixed control speed, ensuring consistent performance regardless of pressure fluctuations.

- Fluctuating pressure has no effect on the control, so the electric FPV maintains its effectiveness and accuracy.

By integrating a multi-tooth element into the shut-off flap body, the control performance is excellent. The tooth profiles ensure a logarithmic flow characteristic, making valve control precise and easy.

Would you like to learn more? We are happy to assist you.

The intelligent control panel for safe and reliable ballast water treatment

The powerful and user-friendly Optimarin control panels manage and log all processes, ensuring smooth functionality and efficient performance of your ballast water treatment system.

Key Features of Our Control Panels

- User-friendly, customized interface for intuitive and efficient operation.

- The 9" widescreen TFT display with touch control offers a clear and engaging user experience.

- Powerful Siemens CPU integrated for high processing capacity.

- Seamless integration with the ship's main control systems via data bus or digital I/O.

- Supports the new OptiLink solution with cloud-based data capture for a centralized and simple overview (OptiLink sold separately).

- GPS connectivity with the ship's GPS to ensure precise position and time synchronization.

- Supports PROFINET (industrial Ethernet) and PROFIBUS (process fieldbus) for efficient communication and integration into existing infrastructures.

- Logging in accordance with the International Maritime Organization (IMO) and U.S. Coast Guard (USCG) requirements.

- Easy extraction of operational logs, alarms, and operational data. Storage via external USB stick or directly in the cloud with OptiLink.

- Simple import and export functionality for operational parameter configuration without onboard service.

- Supports all additional Optimarin features (PMS integration, interlock functionality, fresh water refill, and more).

Would you like to learn more and receive further information about our control panel?

Cleaning in Place System: Efficient cleaning of your ballast water system without disassembly

Our innovative 'Cleaning in Place (CIP)' technology from Optimarin enables fully automated cleaning of the internal components of your ballast water treatment system without disassembly or manual cleaning.

Deposits, biofouling, and other contaminants are removed. Regular, automatic cleaning reduces the risk of blockages and performance losses, thereby maximizing the uptime of your BWTS.

Key Features of Our CIP

- 5 kW immersion heater

- 0.37 kW pump motor

- 1 m³/h flow rate

- 50-liter cleaning liquid tank

- 5 liters of cleaning liquid per cleaning cycle

- Adjustable temperature, standard 60°C

- Adjustable program duration

- Automatic start available

- Ex versions available

- Pneumatically or electrically actuated valves

- Scalable to up to 18 UV chambers

Would you like to learn more? We are happy to assist you.

Key benefits for your organization

Effective and thorough

Our filters effectively remove larger particles and organisms from seawater, while their self-cleaning function reduces maintenance effort and downtime. The powerful UV systems eliminate remaining organisms and provide a high treatment capacity of up to 167 m³/h of water.

Safety through highly efficient components

The pressure control valves provide a logarithmic flow characteristic for precise regulation and prevent instability, while ensuring low cavitation and noise levels.

Modern data monitoring

The modern control panel with high-performance CPU and touchscreen display enables user-friendly operation. A centralized data monitoring system with OptiLink supports integration into ship control systems and allows for easy maintenance through simple log extraction.

Zeppelin Power Systems Services for marine

Services for a reliable ballast water treatment system

From spare parts to training programs – our services for your BWTS

With our comprehensive services for Optimarin ballast water treatment systems (BWTS), we ensure that your system always operates efficiently and reliably

We not only assist with planning and implementation, but also offer regular maintenance services, deliver original spare parts quickly, and provide extensive service kits, including installation materials.

For your onboard personnel, we offer training programs, and our flexible service contracts are tailored to the individual needs of our customers, providing you with complete support.

Zeppelin Power Systems Solutions for Marine

Complete solutions for the demanding maritime industry

Show all Solutions for MarineZeppelin Power Systems Services for marine

Benefit from our wide range of services

Show all Services for MarineZeppelin Power Systems Resources for Marine

Brochures available for Download

Show all Resources for Marine

Optimarin Ballast Water Treatment

You can find more information about Optimarin ballast water treatment in the brochure

Zeppelin Power Systems Portfolio

Explore more from the Zeppelin Power Systems portfolio

Power & Heat

Oil & Gas

Rail

© 2025 Zeppelin Power Systems GmbH