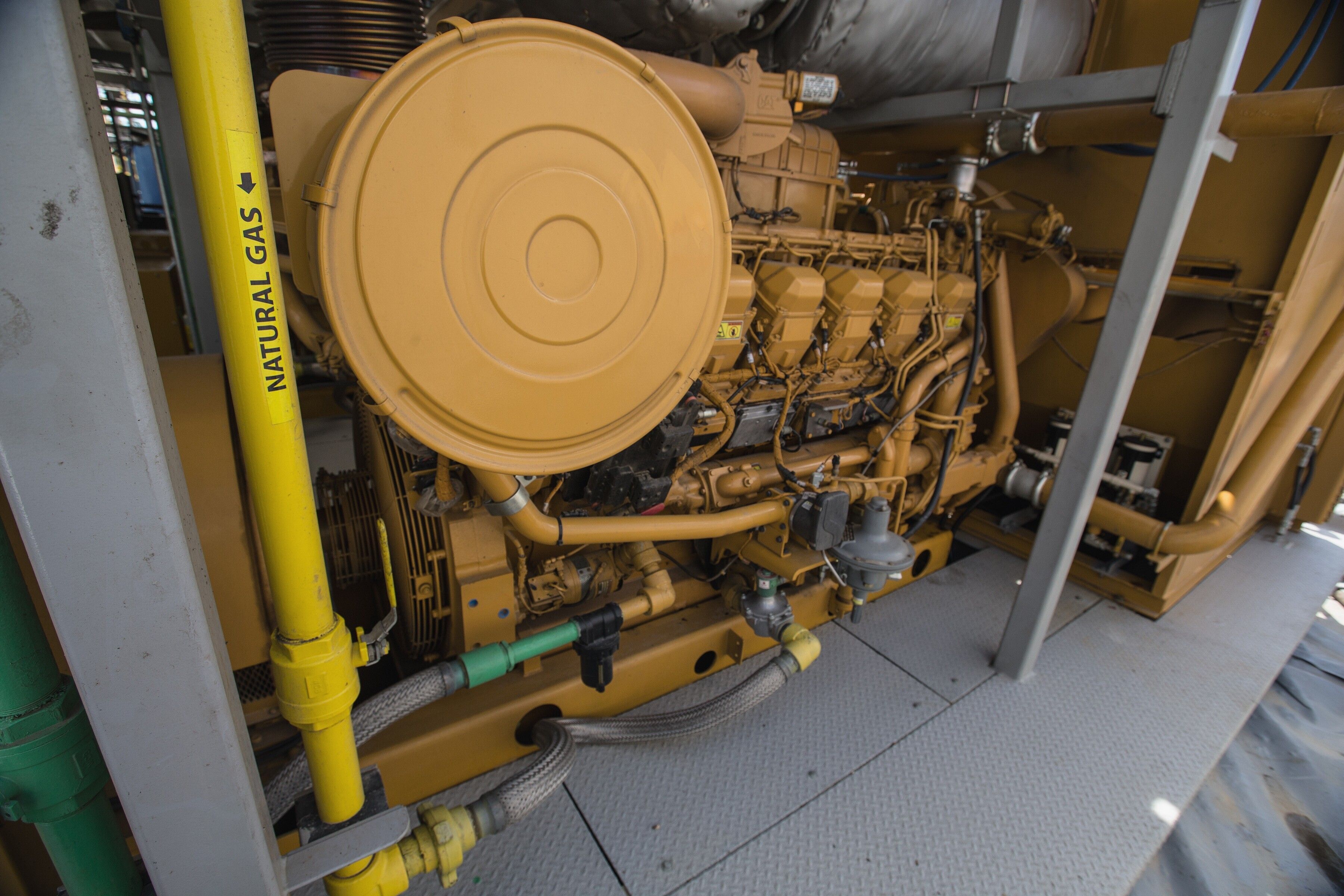

Powerful Cat industrial engines for demanding applications

Power for every challenge

Zeppelin Power Systems offers a wide selection of Caterpillar industrial engines that excel in efficiency, durability, and robust performance. Our engines not only meet the specific requirements of each industry but also comply with current emission standards and environmental regulations, ensuring maximum performance and sustainability.

| Engine Type | Datasheet | Power in kW (hp) | Liter | Cylinders | Aspiration | Speed range RPM | Max. torque in Nm (lb-ft) | Max. speed RPM | Exhaust aftertreatment |

|---|---|---|---|---|---|---|---|---|---|

| C1.1 | 16,1 (22) - 21 (28) | 1,1 | 3 | NA / T | 2.400 / 2.800 / 3.400 | 68 (50) - 86 (63) | 1.600 / 2.100 / 2.400 | - | |

| C1.7 | 18,9 (25) | 1,7 | 3 | NA | 2.200 | 98 (72) | 1.400 | - | |

| C2.2 | 34 (46) - 36 (48) | 2,2 | 4 | NA / T | 2.400 / 2.500 / 2.800 | 140 (103) - 190 (140) | 1.700 / 1.800 | - | |

| C3.6 | 74 (99) - 82 (110) | 3,6 | 4 | TA | 2.200 | 430 (317) - 450 (332) | 1.500 | DOC+DPF | |

| C4.4 | 110 (148) - 129 (173) | 4.4 | 4 | TA / TTA | 1.900 - 2.200 / 2.000 / 2.200 | 560 (413) - 750 (553) | 1.400 | DOC+DPF | |

| C7.1 | 130 (174) - 205 (275) | 7 | 6 | TA / TTA | 1.800 - 2.200 | 842 (621) - 1.257 (927) | 1.400 | DOC+DPF+SCR | |

| C9.3B | 250 (335) - 340 (456) | 9,3 | 6 | TA | 1.800 - 2.200 / 1.800 | 1.530 (1.129) - 2.088 (1.540) | 1.400 | DOC+DPF+SCR | |

| C13B | 340 (456) - 430 (577) | 12,5 | 6 | TA | 1.800 - 2.100 | 2.082 (1.536) - 2.634 (1.943) | 1.400 | DOC+DPF+SCR | |

| C13D | 340 (456) - 515 (690) | 12,9 | 6 | TA | 1.800 - 2.100 | 3.200 (2.360) | 1.300 | DOC+DPF+SCR | |

| C15 | 354 (475) - 433 (580) | 15,2 | 6 | TA | 1.800 - 2.100 | 2.174 (1.603) - 2.655 (1.958) | 1.400 | DOC+DPF+SCR | |

| C18 | 429 (575) - 470 (630) | 18,1 | 6 | TA | 1.800 - 2.000 | 2.694 (1.987) - 2.951 (2.177) | 1.300 | DOC+DPF+SCR |

Do you have questions about our Industrial engines China Nonroad Stage IV? We are happy to advise you.

| Engine Type | Datasheet | Power in kW (hp) | Liter | Cylinders | Aspiration | Speed range RPM | Max. torque in Nm (lb-ft) | Max. speed RPM | Exhaust aftertreatment |

|---|---|---|---|---|---|---|---|---|---|

| C0.5 | 8,2 (11) - 10,2 (13,7) | 0,51 | 2 | NA | 2.800 / 3.600 | 30 (22) | 2.100 / 2.600 | - | |

| C0.7 | 15,3 (21) | 0,76 | 3 | NA | 3.600 | 50 (37) | 2.400 | - | |

| C1.1 | 19,7 (26) - 21 (28) | 1,1 | 3 | NA | 3.000 / 3.400 | 67 (49) | 2.100 / 2.400 | - | |

| C1.5 | 21 (28) - 30 (40) | 1,5 | 3 | NA / T | 2.200 - 3.000 | 96 (71) / 112 (83) | 1.800 | - | |

| C1.7 | 24 (32) | 1,7 | 3 | NA | 2.400 | 105 (77) | 1.800 | - | |

| C2.2 | 34 (46) - 49 (66) | 2,2 | 3 | NA / T / TA | 2.400 - 3.000 | 143 (105) - 200 (148) | 1.800 | - | |

| C2.8 | 50 (67) - 55 (74) | 2,8 | 4 | T | 2.200 - 2.400 | 265 (195) - 300 (221) | 1.600 | - | |

| C3.6 | 55 (74) - 90 (121) | 3,6 | 4 | TA | 2.000 - 2.400 / 2.200 - 2.400 | 424 (313) - 500 (369) | 1.200 / 1.500 | - | |

| 3054 | 56 (75) - 97 (130) | 4,4 | 4 | NA / T / TA | 2.200 | 265 (195) - 500 (369) | 1.400 / 1.700 | - | |

| C4.4 | 75 (101) - 106 (142) | 4,4 | 4 | T / TA | 2.200 | 420 (310) - 558 (412) | 1.400 | - | |

| C7.1 | 112 (150) - 205 (275) | 7 | 6 | TA | 1.950 / 2.200 / 2.500 | 672 (496) - 1.050 (774) | 1.100 / 1.200 / 1.400 | - | |

| C7 | 172 (231) - 223 (299) | 7,2 | 6 | TA | 1.800 - 2.200 / 2.100 - 2.200 | 924 (682) - 1.275 (940) | 1.400 / 1.650 | - | |

| C9.3B | 230 (308) - 310 (416) | 9,3 | 6 | TA | 1.800 - 1.900 / 1.800 - 2.000 / 1.800 - 2.200 | 1.416 (1044) - 1.810 (1335) | 1.400 | - | |

| C11 | 242 (325) - 336 (451) | 11,1 | 6 | TA | 1.800 - 2.100 | 1.487 (1.097) - 2.056 (1.517) | 1.400 | - | |

| C13 | 287 (385) - 400 (536) | 12,5 | 6 | TA | 1.800 / 1.800 - 2.000 / 1.800 - 2.100 | 1.760 (1.298) - 2.364 (1.744) | 1.400 / 1.800 | - | |

| 3406C | 269 (361) - 347 (465) | 14,6 | 6 | TA | 1.800 / 2.000 / 2.100 | 1.696 (1.251) - 2.172 (1.602) | 1.200 / 1.350 / 1.400 | - | |

| 3406C Fire Pump | 218 (292) - 359 (481) | 14,6 | 6 | TA | 1.750 / 2.100 / 2.300 | - | - | - | |

| C15 | 354 (475) - 444 (595) | 15,2 | 6 | TA | 1.800 - 2.100 | 2.171 (1.601) - 2.719 (2.005) | 1.400 | - | |

| C18 | 429 (575) - 597 (800) | 18.1 | 6 | TA / TTA | 1.800 - 2.100 | 2.627 (1.938) - 3.655 (2.696) | 1.400 | - | |

| C18 Fire Pump | 447 (599) - 597 (800) | 18.1 | 6 | TA | 1.500 - 2.100 / 1.750 - 2.100 | - | - | - | |

| 3412 | 465 (624) - 540 (724) | 27 | 12 | TA | 1.800 / 2.100 | 2.757 (2.034) - 2.971 (2.191) | 1.300 / 1.400 | - | |

| 3412C Fire Pump | 476 (638) - 551 (739) | 27 | 12 | TA | 1.750 / 1.900 - 2.100 | - | - | - | |

| C27 | 597 (800) - 858 (1.150) | 27 | 12 | TA | 1.800 - 2.100 | 3.657 (2.697) - 5.255 (3.876) | 1.400 | - | |

| C32 | 709 (950) - 1.007 (1.350) | 32 | 12 | TA | 1.800 - 2.100 | 4.338 (3.200) - 6.166 (4.548) | 1.400 | - | |

| 3508 | 470 (630) - 746 (1.000) | 34.5 | 8 | TA | 1.100 / 1.200 / 1.800 | 3.794 (2.798) - 4.263 (3.144) | 1.000 - 1.450 | - | |

| 3508 Fire Pump | 709 (951) - 794 (1.065) | 34.5 | 8 | TA | 1.460 / 1.750 | - | - | - | |

| 3508B | 746 (1.000) - 820 (1.100) | 34.5 | 8 | TA | 1.800 | 4.353 (3.211) - 4.569 (3.370) | 1.450 | - | |

| 3512 | 761 (1.021) - 1.119 (1.501) | 51,8 | 12 | TA | 1.200 / 1.300 / 1.800 | 6.188 (4.564) - 6.210 (4.580) | 1.000 / 1.400 | - | |

| 3512 Fire Pump | 1.066 (1.430) - 1.193 (1.600) | 51,8 | 12 | TA | 1.460 / 1.750 | - | - | - | |

| 3512B | 1.119 (1.501) - 1.230 (1.649) | 51,8 | 12 | TA | 1.800 | 6.526 (4.814) - 7.180 (5.296) | 1.450 | - | |

| 3512C | 1.120 (1.502) | 58,6 | 12 | TA | 1.800 | 7.130 (5.259) | 1.500 | - | |

| 3516 | 1.011 (1.356) - 1.492 (2.001) | 69 | 16 | TA | 1.200 / 1.300 / 1.800 | 8.282 (6109) - 8.391 (6189) | 1.000 / 1.400 | - | |

| 3516 Fire Pump | 1.417 (1.900) - 1.480 (1.985) | 69 | 16 | TA | 1.460 / 1.750 | - | - | - | |

| 3516C | 1.566 (2.100) | 78 | 16 | TA | 1.750 | 10.254 (7.563) | 1.300 | - | |

| 3606 | 1.490 (1.998) - 2.150 (2.883) | 110.8 | 6 | TA | 750 / 900 / 1.000 | 19.540 (14.413) - 21.150 (15.600) | 615 / 720 / 820 | - | |

| 3608 | 2.088 (2.800) - 2.710 (3.634) | 147.8 | 8 | TA | 800 / 900 / 1.000 | 25.670 (18.934) - 26.660 (19.664) | 656 - 820 | - | |

| 3612 | 2.970 (3.983) | 221.7 | 12 | TA | 750 | 38.950 (28.730) | 675 | - | |

| 3612 | 3.135 (4.204) - 4.252 (5.702) | 295.6 | 12 | TA | 900 / 1.000 | 33.729 (24.879) - 41.822 (30.848) | 720 / 790 / 800 | - | |

| 3616 | 4.050 (5.431) - 5.700 (7.644) | 295.6 | 16 | TA | 765 / 900 / 1.000 | 56.061 (41.351) - 56.900 (41.969) | 650 / 738 / 820 | - |

Do you have questions about our industrial engines UN ECE R96 Stage IIIA and lower? We are happy to advise you.

Caterpillar industrial engines – Powerful drives with comprehensive service from Zeppelin Power Systems

Our Caterpillar industrial engines are renowned worldwide for their reliability, efficiency, and maximum performance. Whether in construction, agriculture and forestry, mining, transport and logistics, recycling, or industrial applications – these robust and durable engines are the core of numerous machines and systems. As an official partner of Caterpillar, Zeppelin Power Systems offers a wide range of industrial engines specifically tailored to the needs of various industries. The offering is further complemented by comprehensive services and digital solutions that ensure maximum machine availability and efficiency.

The requirements for industrial engines vary greatly depending on the application. We offer a wide selection of Cat engines with different power ranges and configurations, perfectly tailored to each application.

In construction, robust and high-performance engines are essential for reliable operation under the toughest conditions. Caterpillar engines are used in road mills, asphalt recyclers, concrete pumps, and other specialized machinery. Particularly suitable engine models such as the C4.4, C7.1, or C9.3 provide high efficiency and fuel savings. For high-demand applications like drilling rigs or cranes, engines such as the C18, C27, or C32 are used, delivering maximum power and reliability.

Efficient drives are also essential in agriculture and forestry. Combine harvesters, forage harvesters, and tractors require engines with high torque at low speeds to save fuel and ensure a long lifespan. The Cat models C7.1, C9.3, and C13 are particularly in demand here. Logging and forestry machines rely on compact yet powerful engines like the C4.4 or C7.1, which provide reliable performance even under challenging conditions.

Caterpillar industrial engines meet the highest environmental and emission standards. Depending on the region and regulatory requirements, the engines are available in various emission classes. The most stringent regulations, such as EU Stage V or EPA Tier 4 Final, are complied with through innovative technologies like Diesel Particulate Filters (DPF), Selective Catalytic Reduction (SCR), and Exhaust Gas Recirculation (EGR). This enables an optimal combination of performance, efficiency, and emission reduction.

However, we offer much more than just powerful engines. With a comprehensive service concept, the company ensures maximum machine availability and efficiency. Custom drive configurations are precisely tailored to the needs of each application. Maintenance and repairs are carried out quickly and reliably through an extensive service network. An optimal spare parts supply ensures that machines remain high-performing over the long term.

Digital solutions enable efficient real-time monitoring and control of your engines. Our telematics systems provide precise analysis of operational conditions, allowing potential issues to be detected and addressed early. With predictive maintenance, maintenance intervals can be optimally planned, reducing downtime and lowering operating costs.

Key benefits for your organization

Maximum reliability and durability

Caterpillar industrial engines are designed for continuous operation under the toughest conditions. They stand out for their robust construction, high-quality materials, and innovative technologies that minimize downtime and ensure a long lifespan. This ensures that machines remain reliable even in demanding environments.

High fuel efficiency and low operating costs

Thanks to state-of-the-art injection technologies and optimized combustion concepts, Cat engines offer exceptional fuel efficiency. The reduced fuel consumption leads to lower operating costs and a more environmentally friendly operation – ideal for applications where cost-effectiveness is a key factor.

Wide power range for every application

From compact 2.2-liter engines for smaller machines to powerful 32-liter engines for heavy equipment – Caterpillar offers an extensive portfolio for a wide range of industries. Whether construction, mining, agriculture, transport, or industry – there is a suitable drive solution for every application.

Compliance with strict emission standards

Cat industrial engines are equipped with state-of-the-art exhaust aftertreatment systems such as Diesel Particulate Filters (DPF), Selective Catalytic Reduction (SCR), and Exhaust Gas Recirculation (EGR). They meet globally recognized emission standards like EU Stage V, EPA Tier 4 Final, and China Non-Road Stage IV, enabling sustainable reductions in pollutant emissions.

Flexibility and customization

Thanks to their modular design, the engines can be flexibly integrated into various machines and applications. Zeppelin Power Systems develops customized solutions that are precisely tailored to the specific requirements – from cooling systems and air filters to control technology.

Comprehensive service and digital solutions

Zeppelin Power Systems not only offers powerful engines but also first-class customer service. This includes global spare parts supply, preventive maintenance concepts, and digital solutions such as remote monitoring and fleet management. This enables customers to operate their machines optimally and proactively address potential maintenance needs.

Cat Financial

Reliable engines and flexible financing solutions from a single source

Custom financing for your engines

As your trusted partner, we offer not only top-quality Cat industrial engines but also flexible financing solutions tailored precisely to your business requirements.

Benefit from our years of industry experience – we are happy to create a customized offer for you!

Zeppelin Power Systems Solutions for Industry

Tailored solutions from a single source

Zeppelin Power System Services For Industry

Benefit from our comprehensive service offering

Show all Services for IndustryEverything from a single source – Your complete solution for energy supply

Our diverse range of solutions and services covers all areas of your energy supply – from initial consultation and precise planning to professional commissioning and ongoing maintenance. Benefit from our comprehensive expertise to improve your energy processes and achieve maximum efficiency.

Planning

- Consulting

- Concept Development

- Project Engineering

Engineering

- Electrical & Installation Planning

- Process Technology

- CAD-based Planning

Project Management

- Site Management

- Technical Procurement

- Quality Assurance

Plant Construction

- Electrical Installation

- Assembly

- Commissioning and Test Run

Service

- Maintenance

- Routine Servicing

- Troubleshooting Service

Zeppelin Power Systems Resources For Industry

Brochures available for Download

Show all Resources for IndustryZeppelin Power Systems Portfolio

Explore more from the Zeppelin Power Systems portfolio

Power & Heat

Oil & Gas

Rail

© 2025 Zeppelin Power Systems GmbH